Hydro invests NOK 200 million at Husnes aluminium plant

Aluminium and renewable energy company Hydro has decided to invest in a new sow casting line at Husnes to increase its primary aluminium casthouse flexibility. This is part of Hydro’s strategy for primary aluminium production and will expand the plant’s product offerings.

The Husnes primary plant, located on the west coast of Norway, produces low-carbon extrusion ingot for the European construction and automotive industries. The sow caster will give flexibility to produce sow ingots in periods of lower demand for the plant’s main products.

“We continue to invest in the future of our Norwegian smelters, which are at the core of Hydro’s strategy to pioneer the green aluminium transition. Adding sow ingots to the product portfolio at Husnes will make us better positioned to take advantage of market fluctuations,” says Hanne Karine Simensen, Executive Vice President of Hydro Aluminium Metal.

The highly automated sow caster will have a capacity of 100,000 tonnes per year. Construction is expected to start in 2025, pending final build decision, with completion scheduled for the first quarter of 2026.

Hydro is investing to meet growing demand for low-carbon primary aluminium

Lower economic activity in Europe over the past couple of years has led to production curtailments at Husnes. Earlier in 2024, Hydro made the strategic decision to use this opportunity of lower activity to complete a full technology upgrade of both lines, effectively making the Husnes plant one of the world’s most modern and energy efficient production sites for primary aluminium.

“Demand for low-carbon aluminium is expected to increase in line with growing consumer awareness and regulatory requirements for materials with the lowest possible carbon footprint. Both Husnes and our other four primary aluminium plants in Norway stand ready to support some of the most forward leaning customers in Europe in reaching their climate goals,” says Simensen.

Hydro Husnes is one of Hydro’s five fully owned primary aluminium plants on the west coast of Norway, with an annual production capacity of 197,000 tonnes of primary aluminium.

Husnes delivers some of the world’s most advanced casthouse products, both low-carbon extrusion ingot and HyForge forge stock, mainly to customers within the construction and automotive sectors in Europe.

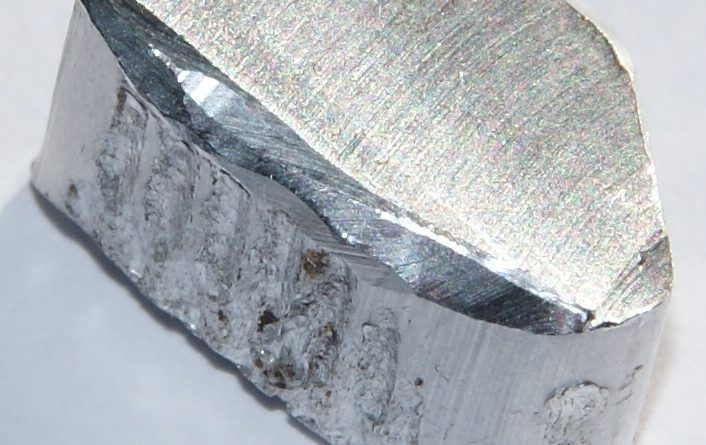

Sow ingots serve as raw material for producing other casthouse products, including extrusion and sheet ingot. They are made by pouring liquid aluminium into molds in highly automated casting lines to ensure consistent quality and typically weigh around 700 kilo each.