Infrared temperature control – key factor in flame hardening success

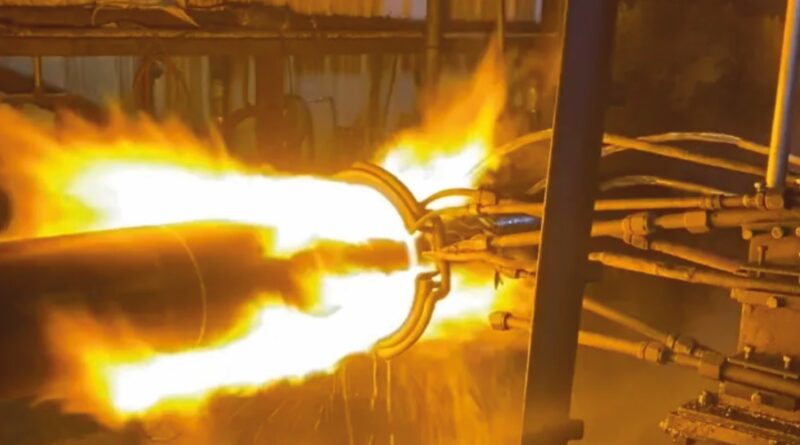

Flame hardening is a heat treatment process widely used on parts made from mild steels, alloy steels, medium carbon steels, and cast iron. This process involves heating the metal’s surface directly with oxy-gas flames until it reaches its austenitisation temperature.

At this critical temperature, the surface structure transforms while the core remains softer and unchanged. Immediate quenching is then required to achieve the desired hardness, as the rapid cooling solidifies a hard surface layer, greatly enhancing the metal’s resistance to wear and corrosion. Before hardening, the steel surface typically consists of austenite or ferrite, which are converted into martensite through flame-hardening.

Flame hardening can be applied either differentially, focusing on specific areas, or uniformly across the entire surface of a workpiece. The success of this process is influenced by several factors, including flame intensity, heating duration, quenching speed and temperature, and the material’s elemental composition. The flame is generated using gases that can achieve high, stable temperatures, most commonly a mixture of oxygen and acetylene, though propane may also be used.

One of the key advantages of flame hardening is its ability to enhance wear resistance, reduce processing times, and minimise distortion while maintaining cost-effectiveness. However, there are also significant challenges. The open flame introduces fire hazards, and the hardened martensite, though tough, can become brittle if overheated, leading to potential cracking and flaking. Furthermore, flame hardening is inherently less precise than other case hardening methods, such as induction hardening or boronizing, and the process can lead to oxidation or decarburisation of the material.

Accurate temperature measurement is not just important, but critical for the success of flame hardening. The precise control of the surface temperature directly impacts the quality of the hardened layer. However, conventional infrared sensors often fall short in this application, as the flame can interfere with the infrared signal, leading to inaccurate temperature readings. Additionally, there is a risk that the sensor might mistakenly register the flame’s temperature rather than the workpiece itself. This emphasis on the criticality of accurate temperature measurement makes the audience feel the importance of this aspect in achieving the desired hardening results and avoiding defects.

When hydrocarbon gases burn, the infrared energy emitted comes not only from the flame itself but also from the by-products of combustion, such as water vapour (H2O) and carbon dioxide (CO2). These gases emit infrared radiation across various wavelengths, which can interfere with accurate thermal measurements taken through the flame. Traditional infrared devices measure the flame, not the part.

To obtain precise thermal measurements in such conditions, it is crucial to use a wavelength region where both water vapour and CO2 have high transmittance. This wavelength allows infrared radiation to pass through with minimal absorption. Additionally, it must be far removed from the intense infrared energy emitted by the flame to avoid interference and ensure accurate readings.

The wavelength band around 3.7µm to 3.9µm is particularly suitable for these measurements. This specific range is chosen because it offers a delicate balance of high transmittance for H2O and CO2 while being relatively free from the radiant energy of the flame itself. This balance ensures more accurate temperature readings through the flame without the distortions caused by the emitted infrared radiation of the flame and combustion gases, making it a practical choice for thermal measurements.

Non-contact methods are essential; using a 3.9µm wavelength, the pyrometer or imager “sees” through the flame and measures the hot metal surface.