Cost-effective solutions for reliable flame-hardening process control

Detecting infrared radiation within this specific wavelength typically requires the use of cooled detectors. While these cameras offer high-precision thermal imaging by reducing sensor noise through cryogenic cooling, they are expensive due to their complex systems and require regular, costly maintenance. Additionally, they have longer start-up times and are larger and heavier, which makes them less practical for large-scale process automation.

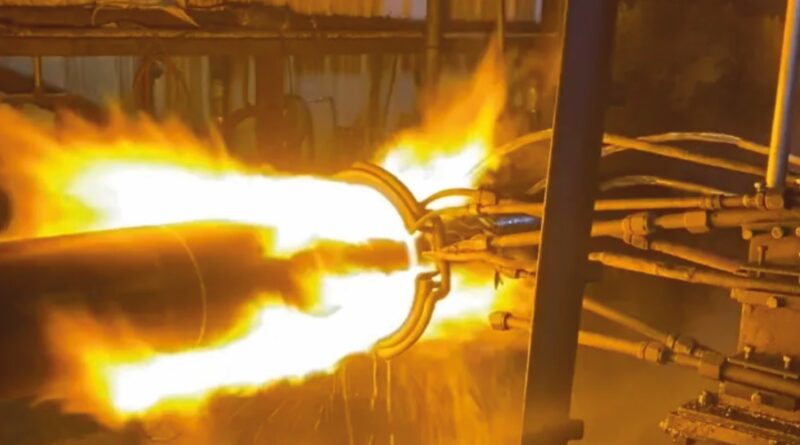

In contrast, the test CTLaser MT pyrometer provides accurate temperature measurement through flames, with a wide temperature range from 200 °C to 1650 °C. Its robust stainless-steel housing, dual laser aiming system, and versatile analogue and digital output options ensure precise targeting and better control of the flame-hardening process, helping to prevent overheating and brittleness.

For imaging needs, the Xi410 MT infrared camera, equipped with a 3.9µm filter, offers an affordable alternative. Although uncooled, it is recommended to use the Xi410 MT in conjunction with the test CTLaser MT pyrometer for enhanced temperature accuracy. The PIC Connect software facilitates this by allowing the pyrometer’s 4-20mA output to correct temperature offsets in the infrared camera.