Automated complete production line for extruded stainless steel tubes

Maruichi Stainless Tube Co. Ltd., one of Japan’s leading manufacturers of stainless steel tubes, has commissioned SMS group to supply a complete production line for the manufacture of extruded stainless steel tubes. As the systems supplier for the new greenfield project in Shimonoseki, Japan, SMS group will provide the full range of quality‑defining equipment. This includes the heating systems and the forming tube extrusion press with associated automation technology.

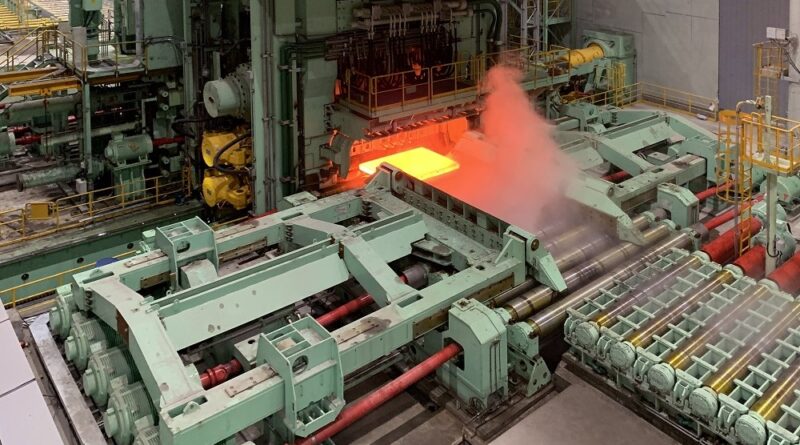

The heating systems to be supplied by SMS are fully electrified and comprise a horizontal preheating system for the billets, an intermediate heating system for precise and flexible heating prior to perforation punching, and a final heating system for precise and flexible heating prior to extrusion. The core forming units comprise an expansion press and a next-generation horizontal tube extrusion press for extruding pre-holed billets with a run-out system including water quench tank. By increasing the extrusion force of the horizontal extrusion press from 20 to 50 meganewtons, Maruichi is expanding the range of possible dimensions for stainless steel pipe production.

The plant will be equipped with a highly automated production system that includes state‑of‑the‑art machinery to optimize the manufacturing process. The suite of automation solutions increase productivity, minimize human error, and ensure consistent quality across all production stages. In addition, the production line will be fitted with the SMS production control system MIDIS (Management Information Diagnostic Indication System), which enables the precise monitoring and control of all processes. MIDIS provides real‑time data analysis and process optimization, ensuring smooth operations and compliance with the highest international standards. The combination of advanced automation and sophisticated quality control consolidates Maruichi’s reputation for reliability and manufacturing excellence.

Construction of the new factory building is scheduled to be completed at the end of 2026, followed by the erection of the equipment. Start-up of production is planned during the 2027 fiscal year, once JIS certification (Japanese Industrial Standards) has been obtained.