Failure and refining effect of purging plugs with different slits

Due to severe service conditions, the life span of purging plugs is shorter than the lining of ladles, which results in lower production efficiency. To investigate the stress distribution, the thermal-solid modeling was applied to simulate the refining process experience by the purging plug.

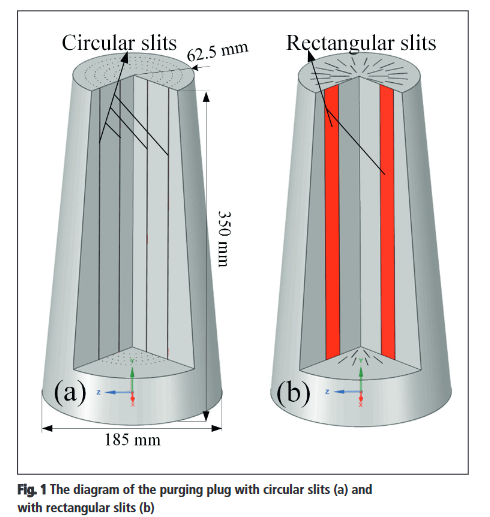

Subsequently, the thermo-mechanical behaviour of purging plug with circular slits and rectangular slits were compared to evaluate structural optimisation. Furthermore, two kinds of the purging plug also were chosen to compare its the mixing time and inclusion removal rate.

To prolong the service time of purging plug, reduce the steelmaking costs and energy-saving, the thermomechanical behaviour and refining effects of purging plug with different slits were compared.

The simulation result shows that instead of rectangular slits, the circular slits not only alleviate the stress concentration around the slit effectively but also reduce the maximum axial tension stress of the purging plug.

Furthermore, the mixing time of the purging plug with circular slits is shorter than that of the purging plug with rectangular slits when the gas flow rate is less than 6,02 Nl/ min.

Besides, the circular slit of a diameter of 0,6 mm is more conducive to generate smaller bubbles. Therefore, the purging plug with circular slits has better performance in the inclusion removal rate.