Electric strip annealing and insulating line for thyssenkrupp

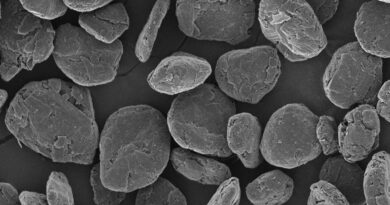

thyssenkrupp Steel Europe (TKSE), has placed an order with SMS group covering the supply of an annealing and insulating line for electric strip. In the annealing and insulating line, the structure of the cold rolled strip will be recrystallized during the annealing process. Thereafter, the material will be provided with an insulating layer.

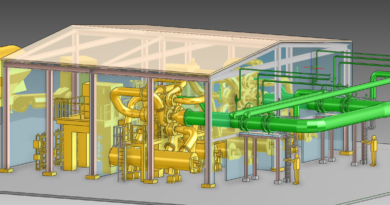

In addition to the entry and exit ends with horizontal loopers, the line will be equipped with an effective cleaning section, annealing furnace, coating section and drying furnace. The finished material will have a width from 700 to 1,350 millimeters and a thickness between 0.2 and 1.0 millimeters.

An outstanding feature of the line is its resource-saving processes and the high degree of automation and digitalization.

The new facility will be integrated in an existing hall and arranged over several floors. For layout and plant planning, the 3D model of the line was transferred to a 3D game engine allowing a full 360-degree view.

Thus, potential collision hazards could be detected at an early stage and it was possible to check and optimize concept suitability. In the upcoming phase of implementation, the 3D model will be particularized and, in the spirit of a transparent planning process, be advanced jointly with thyssenkrupp. This way a digital twin of the plant will be created which will be tested and pre-optimized prior to installation to the proven Plug & Work concept under near-reality conditions.

The technological heart of the line is the heat treatment and coating process. For heat treatment a resource-saving Drever furnace will be installed able to map an optimized annealing curve. For this purpose, the furnace will be equipped with a patented rapid heating system for up to 900 degrees Celsius by a combination of radiant-tube furnace and inductors.

Further heating will be accomplished by electrical heating elements, while several different cooling systems will be installed for subsequent targeted cooling. Using the intelligent furnace concept (I-Furnace) it will be possible to predict material data, such as magnetic properties, with the aid of data-driven models, and thus to intervene in the production process in a prescriptive way.