Rebar minimill with integrated melting, casting, and rolling for Korea

YK Steel, Korea, has commissioned SMS group to supply a new minimill with integrated melting, casting, and rolling and including all electrical and automation systems. Instead of relocating and upgrading an existing plant, originally planned at the end of 2021, YK Steel instead opted for a completely new minimill. This means it benefits from state-of-the-art technologies being delivered and put into service. The minimill will start production in 2025 at the company’s Dangjin site.

This strategic decision to build a new plant underscores the growth plans of Daehan Steel Co., Ltd. of becoming one of the country’s market leaders with YK Steel Co. in the rebar manufacturing sector. The new plant project also aims at achieving more sustainable production at minimal operating costs.

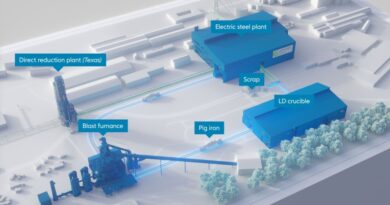

To produce the steel, YK Steel plans to use a 115-ton DC Edge® electric arc furnace and an Aura® charging system, which is operated with 100 percent steel scrap. The five-strand caster, which will produce square billets 150 millimeters thick, can achieve casting speeds of up to four meters per minute thanks to the proven CONVEX mold technology. The cast billets are conveyed into the downstream rolling mill via a hot-charging roller table. This is connected to a walking beam furnace that offers a production capacity of 140 tons of billets per hour and is fitted with low-NOx recuperative burners. The rolling mill consists of 18 new housingless stands and an innovative water cooling system for controlling the rolled stock temperature as well as for quenching.

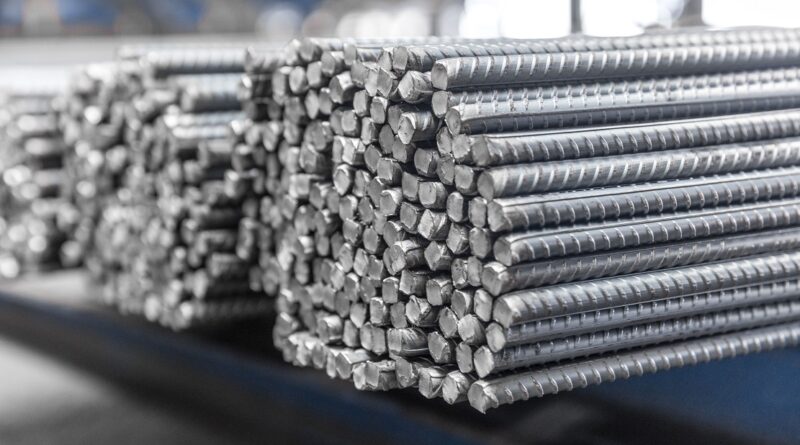

YK Steel will use the new plant to produce reinforcing steel with diameters ranging from 10 millimeters to 35 millimeters.

The products manufactured in the minimill will be sold as six to twelve-meter long part-packages with a maximum weight of 450 to 550 kg and large packages weighing up to two tons.