Alcoa Bécancour Smelter to diversify its product portfolio

To meet the needs of customers, Alcoa will make a US$10 million (C$13 million) investment in the Bécancour smelter to improve the facility’s casting capabiliites.

“Aluminum is a critical material for the future, and Alcoa is the company to deliver it”, said Christian Fortin, General Manager of the Bécancour Smelter. “This investment is excellent news for the Bécancour smelter; as we will be able to serve more customers with an expanded range of product formats and compositions; it is a great opportunity for our smelter.”

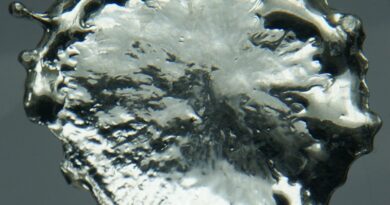

The investment will be directed towards the purchase of new tooling equipment that will allow increased diversification of value-added products, primarily rolling slab for the automotive industry. The new equipment will provide castings with additional dimensions, a smoother surface, better dimensional control and a higher casting speed.

Few slab producers in North America have this new state-of-the-art tooling. In fact, Bécancour will be the first Alcoa smelter to have it, which will allow it to further differentiate itself in the market.

The arrival of the tooling is expected in 2024. Internal teams are already mobilized to turn raw potential into real progress and quickly learn to operate and implement the new casting technology at the smelter.

True to its vision of reinventing the aluminum industry for a sustainable future, the Bécancour Smelter is powered by hydroelectricity and has received the “Performance” certification from the Aluminium Stewardship Initiative. Alcoa owns 74.95% of the Bécancour smelter, which has an annual nameplate capacity of 462,000 metric tons of aluminum with a team of more than 1,200 employees.