Apple to use ELYSIS zero-carbon aluminium for the latest iPhone SE

Aple has announced that it will use zero-carbon aluminium produced by ELYSIS in the new iPhone SE. This is the first time the aluminium will be produced and sold at industrial scale, representing another major milestone in advancing the ELYSIS technology invented by Alcoa. The aluminium to be used in the iPhone SEs is being produced at the ELYSIS Industrial Research and Development Centre in Quebec with renewable hydropower.

This latest announcement builds on Apple’s existing relationship with ELYSIS. Apple contributed funding as a non-equity partner in the ELYSIS joint venture when it was launched in 2018 and a year later made the first ever purchase of ELYSIS aluminium, which was used in 16-inch MacBook Pro laptops.

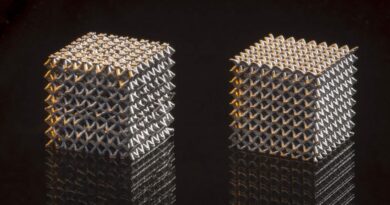

ELYSIS uses a technology that eliminates all greenhouse gas emissions associated with traditional smelting, producing only pure oxygen as a by-product. Last year, ELYSIS constructed the first commercial scale prototype cells of ELYSIS’ inert anode technology at a smelter in Quebec.

The new process, which can be used for both new and existing aluminium smelters, will reduce operating costs of aluminium smelters while increasing production capacity. The technology is on track to be commercially available by 2024.

Apple isn’t the only major company to use ELYSIS aluminium. Last year, Alcoa produced a combination of ELYSIS aluminium and Alcoa’s low-carbon EcoLum aluminium to manufacture the wheels for Audi’s e-tron GT sports car.

ELYSIS is a key part that will help Alcoa realize its vision to reinvent the aluminium industry for a sustainable future. The roadmap includes projects that aim to fundamentally decarbonize key parts of the aluminium value chain. In addition to decarbonizing smelting through ELYSIS, Alcoa is focused on technology, which converts post-consumer scrap material into super high-purity aluminium.