ATHOR’s innovative approach to refractory linings

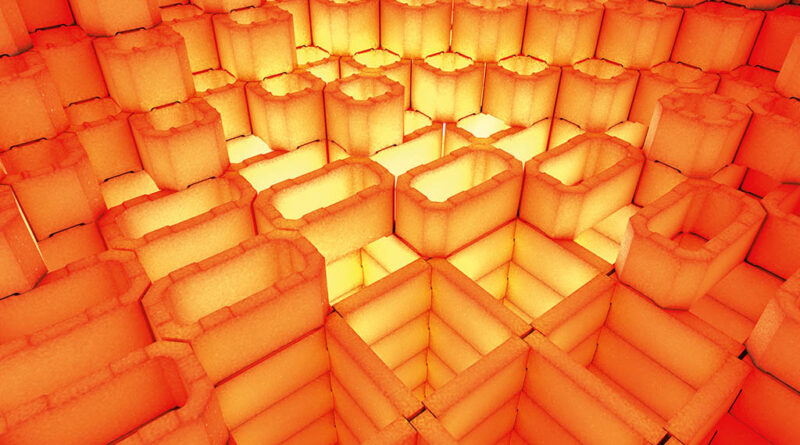

In industry, refractory linings are vital, acting as stalwart protectors against intense heat in numerous applications, notably within the iron and steel sector. However, understanding the thermomechanical behavior of these linings under extreme temperatures is a complex task and one that the ATHOR (Advanced Thermomechanical multiscale modelling of Refractory linings) project is diligently addressing.

Launched in October 2017 as a Marie-Sklodowska-Curie action, ATHOR is an innovative, collaborative, and interdisciplinary European Training Network program. The project combines a rich blend of expertise from 15 early-stage researchers, seven academic beneficiaries, and eight private partners, fostering a knowledge and innovation community in refractory technology.

ATHOR’s Scientific Objective

At its core, ATHOR seeks to deepen our understanding of refractory linings by developing and adapting advanced modeling strategies and experimental technologies. The goal is to perform reliable computations and measurements within the challenging temperature range that these materials endure. In a field where high temperatures can present significant difficulties, ATHOR’s work is an invaluable contribution.

Implications for Industry

The implications of ATHOR’s research extend beyond just theoretical understanding. By developing high-end engineering technologies in materials science and numerical simulations, ATHOR aims to design more robust and reliable refractory linings. This is not a mere academic exercise but a practical initiative with tangible benefits. Durable and dependable linings can reduce refractory costs, increase equipment availability, and enhance process control.

Tackling Environmental Issues

Yet, the scope of ATHOR’s work reaches even further. In addition to the direct operational advantages, the project’s outcomes address pressing environmental concerns. Energy efficiency is a significant aspect of ATHOR’s mission, recognizing that improvements in refractory technology can lead to substantial energy savings. This dual focus on operational efficiency and environmental sustainability aligns ATHOR’s objectives with the interests of industrial partners and broader societal needs.

Looking Forward

As we navigate the increasingly complex landscape of industrial applications and environmental obligations, projects like ATHOR serve as crucial torchbearers. Their work exemplifies the power of collaboration, interdisciplinary research, and a commitment to operational and environmental excellence.

The challenges presented by high-temperature applications are significant. They demand innovation, expertise, and perseverance. The ATHOR project embodies these qualities, pioneering a path forward in the study and practical application of refractory linings. Its contributions will undoubtedly help shape a future where industry not only thrives but also aligns harmoniously with the needs of our planet.