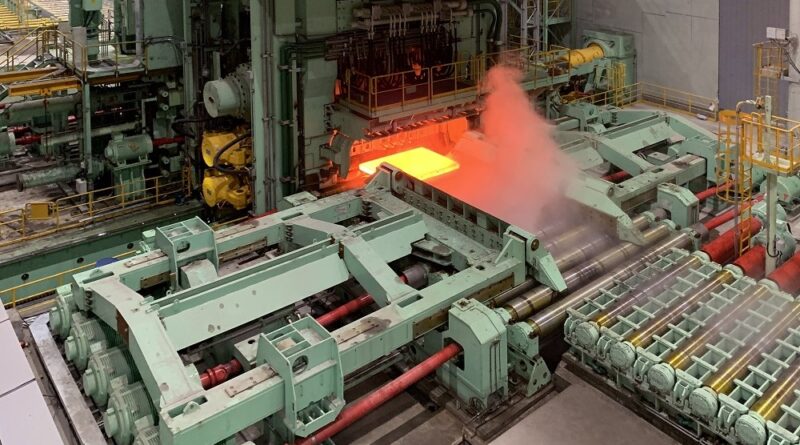

Automation for Steckel mill to enhance reliability at stainless steel plant

Leading Indian steel producer Steel Authority of India (SAIL) has tasked Primetals Technologies with an upgrade of the process automation system at its Steckel mill in Salem, India. Primetals Technologies is responsible for the supply and implementation of Level 2 automation equipment and software.

The existing process automation system dates back to 1995. Conforming to the most modern standards, the new system provides operators with improved accuracy when controlling the rolling process. In addition, SAIL will benefit from increased mill availability. As a result, the modernization will enhance SAIL’s production of stainless steel at the Salem plant.

Automation experts from Primetals Technologies will implement the new system at the Steckel mill while the current Level 2 system is still in operation. The Primetals Technologies team will collect important values and insights related to mill configuration and the production process before switching to the new system. This allows for the implementation phase to be scheduled during planned shutdown periods. Moreover, the new process automation system will run on new hardware that dramatically reduces the need for IT-related maintenance. The Salem Steel plant is part of SAIL’s special steel branch, which has been pioneering the supply of wide-width stainless steel sheets and coils in India. The facility produces austenitic, ferritic, martensitic, and low-nickel stainless steel grades in the form of coils and sheets. The annual production of cold rolled items is at 340,000 tons while the hot rolling mill has a capacity of 364,000 tons per year. Moreover, the plant features India’s first state-of-the-art stainless steel blanking facility with a capacity of 6,600 tons of coin blanks as well as utility blanks and circles annually.