Baosteel orders Bow-Type Caster to produce the world’s largest slab sections

Chinese steel producer Baosteel Zhanjiang has awarded Primetals Technologies a contract for the engineering, supply, and startup of a bow-type 2-strand continuous caster for the production of extraordinarily thick slabs. The caster, designed to be one of the world’s most powerful, will be implemented at Baosteels’s plant in Zhanjiang, Guangdong province. It will produce slabs of record-breaking sections, measuring up to 2,700 millimeters in width at 450 millimeters in thickness.

Primetals Technologies is responsible for the engineering and implementation as well as the supply of mechanical equipment and a comprehensive Level 2 automation package. With an annual capacity of 3.5 million tons of high-quality slabs, the new equipment will enable Baosteel to produce plates for heavy-gauge sectors like the shipbuilding and wind turbine industries. Usually, ingot casters or vertical casters are the equipment of choice for products of these thicknesses. However, both of these are not as cost-effective and efficient as Primetals Technologies’ new type of bow-type continuous slab caster.

Consistent and High Quality

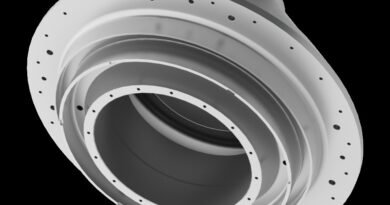

Baosteel’s caster will be equipped with unique Single Roll DynaGap (SRD) segments from Primetals Technologies. When changing parameters that influence production, like steel grade, cooling practice, and casting speed, the process models of the Level 2 automation package dynamically determine the best casting gap, allowing for the SRD segments to optimally adjust individual roll gaps and forces. The caster’s SRD segments can handle capacities of 5,000 kilonewtons per roll, enabling very large thickness reductions in the casting process. This leads to superior internal quality of the cast slabs, and, in turn, results in the production of defect-free ultra-thick plates of high quality.

Mold Level Fluctuations Cut in Half

Another key feature of the caster is Primetals Technologies’ new and ground-breaking method for establishing the ideal caster-roll geometry at the initial design stage. This optimized roll geometry reduces mold level fluctuations stemming from unsteady bulging by 50 percent, enables higher casting speeds, and leads to greater productivity. A wide spectrum of parameters, such as targeted steel grade, section size, and casting speed, is taken into account by the software tool when it calculates the optimized geometry. As a result, it identifies just the right frequency spectrum for the rolls.

Reduced Energy Consumption

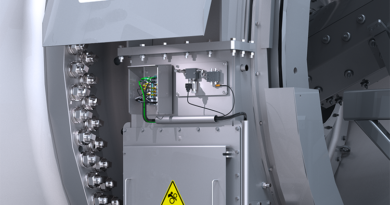

Primetals Technologies will implement the proven DynaFlex oscillator concept featuring a special design concept – engineers at Primetals Technologies have found a way to compensate for heavy mold weights by utilizing helical springs. Among the benefits is significantly reduced energy consumption levels.

The continuous bending and straightening concept from Primetals Technologies, Smart Segments, together with a dry-casting machine design that includes Eco Star rolls contribute to significantly improved slab-surface quality. The Eco Star rolls’ internal cooling system is capable of enduring the high temperatures needed to minimize surface defects during the dry-casting process.

A part of the China Baowu Steel Group Corporation, which is a Fortune Global 500 enterprise, Baosteel represents an integrated iron and steel company that operates several plants, including locations in Shanghai, Wuhan, Meishan, and Zhanjiang, and others. Baosteel’s product portfolio encompasses a wide range of flat and long products based on carbon, low-alloyed, alloyed, and silicon steel grades for use in various applications.