BHP and China’s HBIS to reduce carbon emissions in steelmaking

In a landmark agreement, BHP and China’s HBIS Group Co., Ltd (HBIS) forge a partnership to pioneer reduced carbon emissions in the steelmaking sector. The collaboration concentrates on groundbreaking trials, including direct reduced iron (DRI) production using BHP’s iron ores and advancing enhanced lump stage 2 trials, aimed at minimizing blast furnace (BF) carbon emissions.

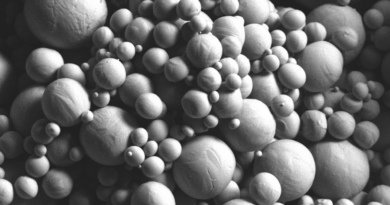

The partnership aims to trial commercial-scale DRI production at HBIS’s new DRI plant, employing BHP iron ores in blends. The DRI process uses hydrogen-rich gas byproducts, converting ore into a metallic iron product, further refined for steelmaking, focusing on reducing carbon footprints.

Additionally, the enhanced lump stage 2 trial seeks to cut carbon emissions by augmenting the use of direct charge lump, reducing reliance on agglomerated feed requiring fossil fuel energy.

This collaboration, building on the 2021 MoU, intends to invest up to $15 million over three years. BHP’s CEO, Mike Henry, emphasizes HBIS’s pivotal role in exploring pathways to slash greenhouse gas emissions in steelmaking, aligning with BHP’s sustainability goals.

Vandita Pant, BHP’s Chief Commercial Officer, highlights DRI’s significance in their journey toward near-zero-emission steel production and applauds HBIS’s partnership in demonstrating the use of BHP iron ores in these production trials, foreseeing pathways to slash carbon emissions.

The agreement extends beyond prior collaborations, encompassing various joint initiatives, including research and development phases, CCUS pilot trials, and enhanced lump stage 1 trials. HBIS Chairman Yu Yong underscores their aligned vision to develop greener, low-carbon solutions, spotlighting this collaboration as a milestone in forging a low-carbon raw material supply chain.