BHP to expand nickel production amid high metal demand

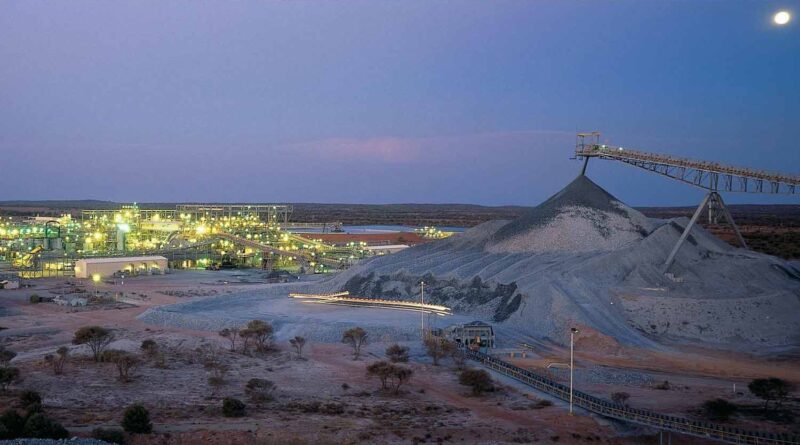

BHP plans to expand nickel production at its Mount Keith mine in Western Australia by 40 per cent, with a new semi-autogenous grinding (SAG) mill, flotation technology and two new Liebherr excavators, BHP Nickel West asset president Eddy Haegel said

One of the world’s most sustainable nickel producers, the Mount Keith operation is expanding to a 15 million tonne per annum operation. “We discovered that unlike stainless steel, Nickel West was remarkably well positioned to support the emerging battery sector,” Haegel said.

“We discovered that nickel is the most important metal to produce high-intensity batteries for electric cars and that we are one of the leading nickel powder producers – a product that remains one of the lowest cost pathways to producing nickel sulphate.”

Nickel sulphide and laterite ore is used to make nickel metal, predominantly for the production of stainless steel as well as nickel sulphate, a key ingredient in the batteries that drive electric vehicles.

More than two thirds of global nickel production is used to produce stainless steel. It is the addition of nickel that enables stainless steel to become such a versatile alloy.

BHP now sells more than 75% of its nickel production to the electric vehicle battery materials industry. Last month, BHP signed a nickel supply agreement with one of the world’s leading sustainable energy companies, Tesla Inc.

BHP will supply Tesla Inc. with nickel from its Nickel West asset in Western Australia, one of the most sustainable and lowest carbon emission nickel producers in the world.

Tesla Inc. is the world’s largest manufacturer of electric vehicles and battery storage systems with a mission to accelerate the transition to sustainable energy, and nickel is a key metal used to manufacture Tesla Inc.’s battery technology.

BHP Chief Commercial Officer, Vandita Pant, said: “Demand for nickel in batteries is estimated to grow by over 500 per cent over the next decade, in large part to support the world’s rising demand for electric vehicles.”

“The Mount Keith concentrator expansion will involve installing a third and much larger 16 megawatt SAG. Together with the modernisation of the flotation circuit, we will increase the concentrator from 10.5Mtpa, to 12Mtpa, and eventually 15Mtpa,” he said.

“The SAG has been ordered from Metso Outotec as a pre-commitment, as the project completes the final detailed design stage, before execution approval at the end of the financial year.” A new flotation circuit which looks to increase recovery of ultrafine nickel particles using Concorde cells from Metso Outotec.

Concorde cells use high pressure flows of slurry into an impact zone to force the bubbles and particles to attach. BHP will also install a flash flotation circuit at Mount Keith, with both new circuits expected to be complete by mid-2022.

The deployment of Liebherr 9600 and 9400 excavators will add to the cause, as the operation ramps up to its 15Mpta goal. Once the all-important infrastructure is in place, BHP will look to initiate Stage I expansion at Mount Keith, increasing mining activity by 50 per cent.

BHP will also build new nickel mines and wind farms in Western Australia as it looks to accelerate away from the fossil fuel sector and prove its green credentials to electric car makers.