Delivering superior metallurgical flotation performance and energy efficiency

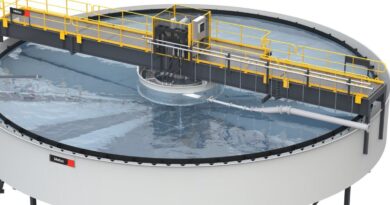

Metso Outotec is introducing the next generation of its ColumnCell flotation cells to the market. The new Metso Outotec ColumnCell leverages the company’s legacy technologies, as well as state-of-the-art best practices, delivering superior metallurgical flotation performance and energy efficiency for a wide range of applications and duties.

“In designing the new ColumnCell, current and future customer needs were carefully studied. Optimized grade is especially important in cleaner circuits and can lead to significantly higher throughput for the entire flotation circuit. Flotation of fines requires specific features: high collection with smaller bubbles to guarantee good recovery, a less turbulent regime and good slurry distribution to avoid bypass, as well as a thicker and more selective froth to generate better product quality. We have designed ColumnCell™ to provide all these features, while also taking into consideration the ore type and the specifics of each project,” explains Antti Rinne, Flotation Vice President at Metso Outotec.

For optimized performance of column flotation, Metso Outotec offers three sparger technologies: Microcel Static mixer, SonicSparger Vent and SonicSparger Jet. All three sparger options can be replaced online to maximize equipment availability and production rate and to reduce energy consumption due to fewer shutdowns and startups.

Metso Outotec has one of the widest portfolios of flotation solutions on the market. The company’s extensive experience in process planning combined with its installed base enables Metso Outotec to design and deliver complete optimized flotation circuits catering to all types of applications and ores. Over the years, Metso Outotec has delivered close to 300 flotation columns worldwide. The company’s comprehensive service portfolio extends from spares and wears to advanced life cycle services and is backed by a global network of industry-leading service expertise. The wide variety of upgrades enables the restoration of outdated existing technology for optimized flotation performance and the achievement of sustainability targets.