Direct pouring on automatic high-pressure green sand moulding line

Foundrymen are often faced with the problem of finding a suitable casting and feeding technique for castings that are difficult or impossible to ingate from their perimeter. This may be due to the nature of the component or limited space on the pattern plate.

With Foseco’s new KALPUR development, foundrymen can for the first time apply the direct pouring technique to automatic green sand moulding lines. This means that the specific advantages of direct pouring, such as improved yield and directional solidifcation can now be realised on moulding lines where access to the cope is not possible.

How does the system work?

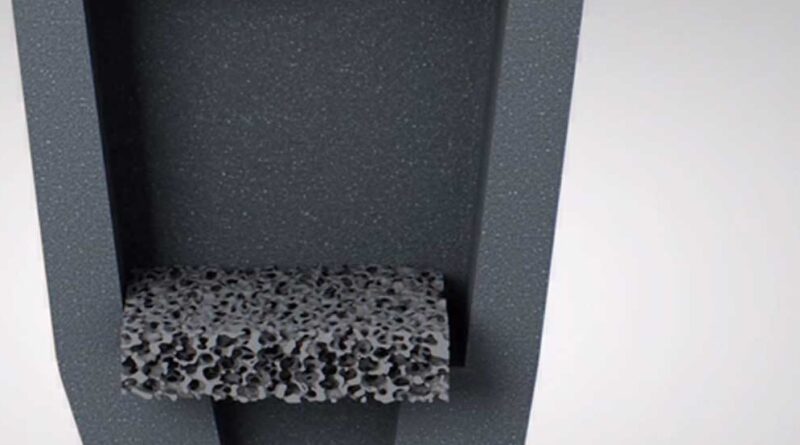

The feeder is placed on the self-centering pin attached to the pattern plate, and also serves as a sprue. The integrated SEDEX filter moves into a vertical position by means of a folding hinge.

The moulding and compaction process is initiated, the breaker core is compressed which compacts the moulding sand in the area of the feeder neck. When the pattern plate is removed, the ceramic foam filter falls back into its initial position.

After positioning of the cope mould and milling of the pouring cup, the casting process can begin. At the end of the casting process, the filter floats to the surface to facilitate the feeding process.

This novel KALPUR direct pour device consists of three critical components:

- A high density, high strength FEEDEX exothermic feeder with a metallic lid, suitable for application on high pressure moulding.

- A SEDEX ceramic foam filter to minimise inclusions and reduce turbulence in the mould

- A patented collapsible breaker core.

What advantages does this system have?

- Reduced fettling costs

- Reduced non-metallic inclusions

- Lower turbulence related defects

- Improved directional solidification

- Good surface finish optimised yield

- Increased space on the pattern plate

- Easier handling of the casting spray, reducing accidental damage