ELYSIS selects Alma smelter for 450 kA inert anode prototype cells

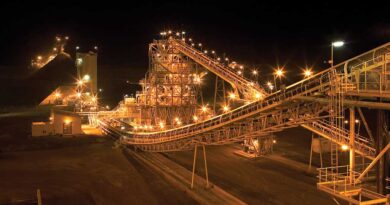

MONTREAL – ELYSIS has announced it has selected the Alma smelter, operated by Rio Tinto in Saguenay-Lac-Saint-Jean, Quebec, for the first installation and demonstration of its inert anode technology at a commercial size of 450 kiloamperes (kA), which is a common capacity for modern, full-scale smelters.

ELYSIS is a joint venture company, led by Alcoa and Rio Tinto, that is working to commercialize a new technology to make aluminum that eliminates all direct greenhouse gases (GHGs) from the traditional smelting process and instead produces oxygen.

As part of its technology development and scale-up, ELYSIS will install industrial inert anode prototype cells at the end of an existing potline at the Alma smelter to demonstrate the technology’s effectiveness at a commercial scale in an industrial operating environment.

This will build on ongoing work at the nearby ELYSIS Industrial Research and Development Centre, also located in the Saguenay region of Quebec.

ELYSIS plans to commercialise its breakthrough technology in 2024, for use in retrofitting existing smelters and installation in new facilities.

INVESTMENT BY THE GOVERNMENT OF QUEBEC

The 450 kA cells at Alma will be supported by a $20 million CAD investment from the Government of Quebec to help bring forward the start of work at the site and to further strengthen the capability of manufacturing businesses in the region to supply specialized equipment required for the ELYSISTM technology.

THE TECHNOLOGY AT A GLANCE

- The ELYSISTM technology addresses the global trend towards producing low carbon footprint products, from mobile phones to cars, planes and building materials.

- The new process will reduce operating costs of aluminium smelters while increasing production capacity. It could be used in both new and existing aluminium smelters.

- In Canada alone, the ELYSISTM technology has the potential to reduce GHG emissions by 7 million tons, the equivalent of removing 1.8 million cars from the roads.

- ELYSIS will also sell next-generation anode and cathode materials, which will last more than 30 times longer than traditional components.

ELYSIS continues to work closely with Alcoa’s Technical Center, where the zero-carbon smelting technology was invented, and the Rio Tinto technology design team in France.

Alcoa’s Technical Center supports ELYSIS in the manufacture of proprietary materials for the new anodes and cathodes that are essential to the ELYSISTM process. The Rio Tinto technology team in France is creating commercial scale designs for the ELYSISTM technology.

ELYSIS is a technology company that was created thanks to a ground-breaking partnership between two global industry leaders – Alcoa and Rio Tinto. ELYSIS’ goal is to revolutionize the way aluminium is produced across the globe.

The process eliminates all direct greenhouse gases from aluminium smelting, and instead produces pure oxygen. Alcoa, Rio Tinto, the Government of Canada and the Government of Quebec provided a combined investment of $188 million (CAD) to create ELYSIS and to see this technology reach commercial maturity in 2024.