Feralpi increases productivity after revamp of 6-strand billet caster

Italian steel producer Feralpi Siderurgica (part of Feralpi Group) has granted the final acceptance certificate (FAC) to Primetals Technologies for a revamp of its 6-strand billet caster at the steel plant in Lonato del Garda, Italy. The implementation of the revamped caster was executed within just six weeks during the planned summer shutdown of 2023. The project lasted only 12 months from contract signature until first cast – usually, similar projects take at least 1,5 years until completion.

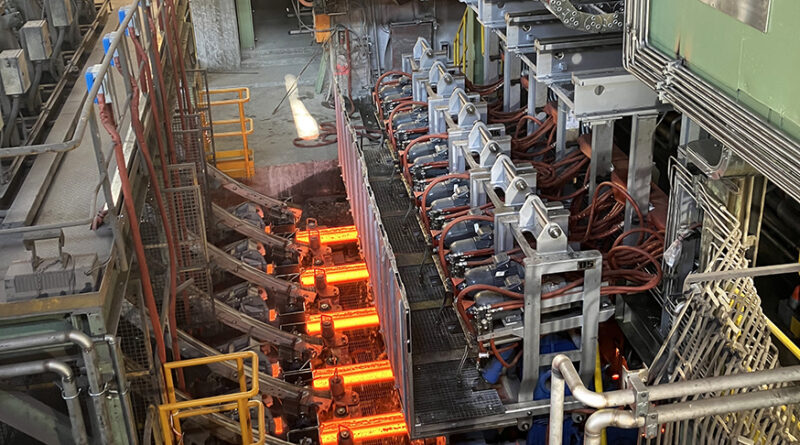

The extraordinarily short implementation was made possible thanks to special design features tailored to Feralpi’s needs, and close knowledge sharing and collaboration between Feralpi’s and Primetals Technologies’ technicians. Primetals Technologies engineered the caster bow in one piece for all six strands and, in addition, preassembled the equipment before it was transported to the Feralpi location. Moreover, the molds and retractable oscillators were also designed and built in one unit, all of which contributed to the smooth implementation on site.

Mold Changes During Casting Sequences

Primetals Technologies has installed retractable oscillators as part of the revamp project, resulting in increased productivity. For conventional billet caster designs, changing a mold implies a complete production stop on all strands. The retractable oscillators, however, are mounted on mobile carriages meaning that every individual oscillator can easily be detached for mold changes. The configuration allows operators to exchange molds on one strand while the other strands continue operation.

Improved Center Quality of Billets

Primetals Technologies’ scope of supply encompassed key mechanical equipment including the caster bow, retractable oscillators, strand guiding units, drive adoption of the withdrawal strand unit (WSU), and a pinch roll. A comprehensive electrics and automation solution for the mold/oscillator, including the LevCon Autostart function, and implementation services, rounds off the scope.

Increased Mold Level Stability

As part of the project, Primetals Technologies’ automation experts have studied the plant in collaboration with Feralpi engineers and explored areas for optimization to increase production performance. The evaluation showed that the response times for the withdrawal drives could be improved. In addition, the team from Primetals Technologies implemented a new set of parameters for LevCon based on a numerical optimization approach.

The new state-of-the-art LevCon function for open stream casting is a solution for enhanced mold level control. This optimization measure has resulted in an improvement by 34 percent on average for the standard deviation of the mold level, i.e. the value indicating mold level stability. Feralpi has shown their satisfaction with the project, stating that the new technology has set a new standard for precise mold-level control. LevCon’s autostart function is now part of the ongoing operations at Feralpi, resulting in a minimized number of breakouts.

Feralpi Group which controls several international companies, is a leading supplier to the European construction industry with an annual production capacity of 2.45 million tons. Feralpi is recognized for its well-developed circular economy initiatives, and 98.6 percent of its steel is produced with recycled and recovered materials or by-products. The group operates several subsidiary companies in Italy and has production and sales locations in Europe and North Africa. Founded in 1968, Feralpi Siderurgica is the oldest company in the Feralpi Group and is a key European supplier of reinforcing steel, wire rod, reinforcement meshes, and the associated derivatives.