Fluke & Comtest’s Acoustic Imager Technology for Partial Discharge

Rising energy costs and more stringent legislation guiding sustainable practices are spurring companies to re-evaluate processes and seek new tools and technologies to reduce waste and overcome challenges in today’s industrial environments.

Fluke, locally represented by COMTEST, a global technology leader in the manufacture of compact, professional electronic test and measurement tools and software, today shares the top three trends that are enhancing operational efficiency in today’s industrial environments.

Challenges posed to industrial operations managers by the pandemic have now been superseded by the rising cost of energy, and the need to deliver on net zero ambitions. As the price of energy continues to increase, the need to reduce costs and deliver on shared sustainability goals intensifies for small-to-medium sized enterprises through to large corporations.

Paul Feenstra, Vice President Fluke (Europe, Middle East & Asia) EMEA, at Fluke said: “We are working together with our customers to help drive new initiatives to improve operations, increase efficiencies, and take reliability to a new level in the 21st century.”

1. Reducing energy costs with upgraded technology and cloud-based data monitoring

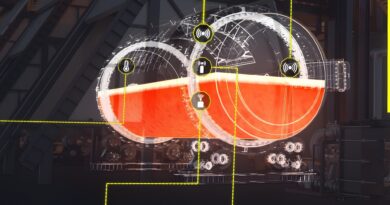

Approximately 90% of all companies use compressed air in some aspect of their operation, such that it is often referred to as the fourth utility. Recent developments in industrial acoustic imaging technology have enabled the fast identification of leaks in compressed air systems used in industrial and manufacturing environments. Fluke’s ii900 Industrial Acoustic Imager features an array of microphones, providing visualisation of sound field within an expanded field-of-view and on a distance of up to 70 meters, that enables maintenance teams to visually locate air leaks very quickly and accurately in compressed air systems.

2. Using data to deliver predictive maintenance

For generations, maintenance professionals have used preventive maintenance to avoid equipment failures and turned to reactive maintenance when assets fail. With the emergence of Industrial Internet of Things (IIoT) technologies, maintenance professionals can now connect tools, software and sensors to collect, store and analyse multiple data sources in one place. The pandemic accelerated investment in technologies that make remote monitoring possible. The technology enables reliability and maintenance teams to meet up-time requirements no matter how fluid on-site staffing might be. The trend for remote monitoring will continue, with small-scale operations turning to remote condition monitoring services.

3. Digital SI speeds the integration of critical equipment measurements The accelerated uptake in digital measurement solutions for industrial applications can save time and money, whilst facilitating a shift towards predictive maintenance for systems. Although modern measurement digital devices are typically not fit-and-forget solutions, the increase in digital measurement solutions paves the way for verification technologies that can help to reduce the maintenance burden on personnel, without compromising on accuracy or reliability.