Greening the power source of energy-intensive smelting

Traditional metal production is inherently polluting, it’s currently responsible for 9% of global greenhouse gas emissions. So, with pressure mounting on the sector to go green (or at least as green as possible), what initiatives are being proposed to reduce the carbon footprint of smelting?

Many of the metals produced in smelting operations around the world will play a vital role in the energy transition. For example, nickel and cobalt, are used in electric vehicle (EV) batteries, while metals like copper and aluminium are increasingly used in decarbonising power generation. Given these end uses, there is a growing desire to produce metals with little-to-no carbon footprint.

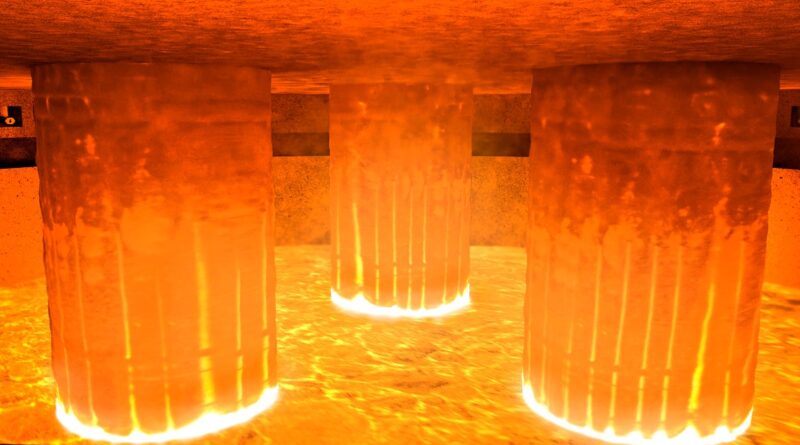

Smelting is highly energy-intensive. Traditionally, the power for smelting has come from either grids using both renewable and non-renewable sources or via onsite generation from hydrocarbons or coal. Sustainable smelting will therefore require greening the energy supply to smelting plants through a 100% renewable grid, clean onsite generation or buying into offsite renewables.

Smelters are already making commitments to power their operations either partly or wholly through dedicated solar and wind power from partners and third-party companies in the next few years.

While using renewable energy can remove carbon emissions from the power used in smelting, it cannot decarbonise the process completely. When metal ore is decomposed using a source of carbon such as coke or coal as a reductant, CO2 is inevitably created as a by-product.

One solution is carbon capture. Captured CO2 can be stored in depleted oil and gas fields, or deep saline aquifers. It can also potentially be injected in liquefied form into suitable rock formations, or sequestered into concrete. Another technique is to re-inject the CO2 from furnaces as part of a synthetic gas for use as part of the process chemistry.

These approaches are still in their infancy, but we expect significant progress in the future.

One alternative to producing new metal from ore is to extract and reuse the raw materials from old lithium-ion batteries. When batteries reach the end of their lives, they are collected, dismantled and shredded. The shredded material is then processed to produce a powdery substance known as black mass.

The exact composition of black mass depends on the particular feedstock, recyclers and recycling process involved, but it will largely comprise various battery metals including lithium, cobalt, nickel and manganese. These can then be separated out through further processing and returned to the battery supply chain.

However, making black mass recycling scalable and cost-effective will require significant investment, as well as the establishment of standardised material specifications between producers and customers. The battery raw materials sector has seen numerous examples of producers being unable to consistently achieve refined battery quality material specifications, such as in the case of lithium.

The black mass recycling sector will likely face this same hurdle as new technologies become developed and proven in the sector. Therefore, a crucial aspect of standardisation will be not only the establishment of product quality specifications, but the consistent ability of producers to achieve them.

One technology which has enormous potential in metallurgical operations is so-called ‘green’ hydrogen, that is, hydrogen produced from water by renewables-powered electrolysis in an essentially clean process.

Hydrogen can essentially replace the use of carbon in smelting, preventing CO2 being emitted at all. However, there are a lot of obstacles to overcome before this becomes a viable large-scale option.