HYDRO Aluminium: The role of Research and Development

The R&D center at Sunndal houses 40 employees, who work with extrusion ingots, foundry alloys, and various other projects that focus on product development and optimizing operations at Hydro casthouses. The R&D center also carries out quality control for Hydro casthouses, such as taking samples of billet to verify a stable process and consistent quality. If there are trends in certain negative directions, the R&D team can suggest actions to be taken by the casthouses.

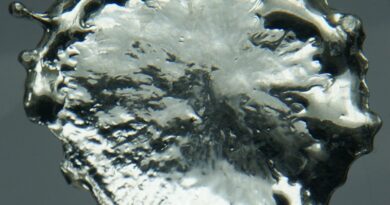

The R&D center has a well-equipped metallographic and material testing laboratory to also support customers with technical service and troubleshooting. “For example, with the scanning electron microscopes, you can analyze defects of a product in detail,” said Stig Brusethaug, R&D manager at the research center. “Is it an impurity or an inclusion? If it’s an inclusion, you can analyze what kind of elements are in it and where that might come from. Our electron scanning microscopes are key instruments in our technical support work.”

The role of the R&D center is extremely varied. For the development of new alloys for the market, they often work on different types of projects together with the customers or end users. This can be either small tasks or larger projects over several years aimed at finding solutions and optimizing the use of aluminium in different applications. “As for casthouse technology development, there is a very close cooperation between Hycast and the R&D center, where Hycast utilizes our capabilities to also do development, prototype testing, and evaluation of equipment and its performance,” said Brusethaug. “The dynamics between Hycast and R&D through our facilities form an integrative new way to develop technology.”