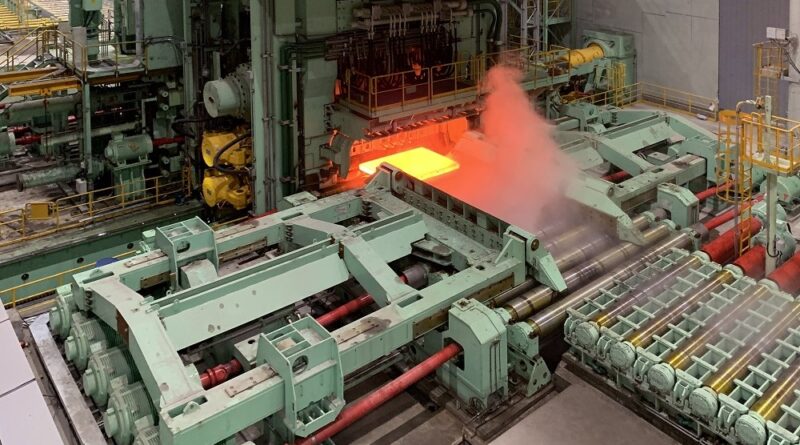

JSP and Primetals Technologies to modernize plate mill in India

Jindal Steel and Power (JSP) has tasked Primetals Technologies with supplying and implementing a comprehensive Level 1 and 2 automation system upgrade at its 5-meter plate mill in Angul, Odisha province, India. The upgrade will improve system availability and ensure a stable supply of spare parts.

First of its Kind in India

Primetals Technologies will supply new hardware and migrate the existing application software for the mill’s main rolling area. The upgrade includes the advanced SIMATIC S7-1500 control system and the latest WinCC software, both part of the totally integrated automation (TIA) portal. This marks the first-ever installation of this automation platform at a plate mill of this size in India.

The project also includes full virtualization of all servers, making lifecycle management of the automation infrastructure smoother and more efficient.

Designed for Shorter Downtime

JSP’s 5-meter plate mill has a capacity of 1.2 million tons annually and produces plates ranging from 5 to 350 millimeters in thickness and 900 to 4,800 millimeters in width. Key automation functions, including the human-machine interface (HMI), will be retained during the migration. As a result, operators and maintenance personnel will be familiar with the system from day one, allowing for a shorter ramp-up period and accelerating the return to full production.

Currently, the outdated automation system at the Angul site is a major cause of unwanted downtime for JSP. Installing the latest hardware and software will improve production stability and allow for seamless integration of future software packages and system updates.