LKAB: New operational plants by 2027

Subject to an efficient environmental permit process, it is estimated that both LKAB’s production of apatite concentrate in Kiruna and Malmberget as well as the industrial park for further processing into critical minerals – including the production of sulphuric acid, based on pyrite from the Aitik mine – could be operational in 2027.

Using pyrite as a basis for producing sulphuric acid is a known technology, but to be able to make these large investments long-term collaboration is necessary – which the two Swedish mining companies see great opportunities in.

The volumes of pyrite concentrate are unlikely to cover the full amount that LKAB needs to produce the volume of sulphuric acid required. In the first instance LKAB will produce phosphorus and rare earth elements from the ongoing mining, but in the future could also expand production by extracting these from mining waste that has been deposited previously.

If this becomes a reality, even more sulphuric acid will be needed. In this case, additional pyrite-containing raw materials will be required, which Boliden in cooperation with LKAB can produce if the Laver deposit goes into production.

Facts about Boliden’s planned extraction of pyrite concentrate

- At Boliden’s Aitik mine south of Gällivare, ore deposits of chalcopyrite containing copper, gold and silver are mined

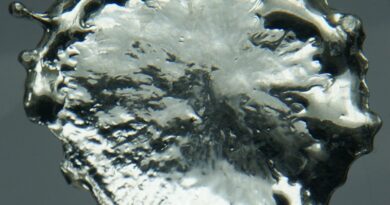

- In the course of extraction and processing, waste rock and non-valuable mineralisations are separated from the copper, gold and silver; the tailings that are separated and deposited contain pyrite

- The pyrite mineralisation contains sulphur and iron oxide (hematite)

Facts about LKAB’s planned production of critical minerals

The EU classifies phosphorus and rare earth elements as critical minerals:

- They are important for EU economy

- Necessary for sustainable agricultural production

- Used in e.g. electric cars and wind turbines

- High import dependency and risks to security of supply

The ores that LKAB mines to produce iron ore also contain phosphorus and earth elements; LKAB is now developing methods of extracting these from what is currently mining waste that is deposited. In a first step apatite concentrate will be extracted by constructing apatite plants in Kiruna and Gällivare/Malmberget.

The apatite concentrate will then be processed further into phosphorus, rare earth elements and fluorine at an industrial park that will be built in Luleå or Skellefteå (location currently being investigated)

LKAB aims to establish a new industrial standard for mineral processing that is fossil-free, electrified and circular:

- The further processing uses hydrochemical processes in which the material is dissolved in hydrochloric acid and separated

- Hydrogen is used to produce the ammonia instead of natural gas

- Own circular production of sulphuric acid, based on pyrite instead of fossil petroleum products

- Sulphuric acid is used to recycle (regenerate) the hydrochloric acid continuously

- Regeneration of the hydrochloric acid produces gypsum as a by-product, which LKAB purifies into a valuable product to avoid depositing it

- From 2027 LKAB could become a significant producer of critical minerals for agriculture and clean technology:

- 5 times Sweden’s need for phosphorus mineral fertiliser

- 30% of Europe’s need for rare earth elements

- Sweden’s entire need for gypsum