New Combination mill installation at Baoshan Iron and Steel

Primetals Technologies has recently completed an installation at Baoshan Iron and Steel in Shanghai, China, for a new combination mill featuring both a wire rod mill outlet and bar-in-coil line to produce 600,000 tons per year of wire rod and bar products. This installation is Baoshan’s first greenfield long rolling investment since the original mill installation in 1998. The new mill is specifically designed to increase rolling mill capacity and expand size range with the wire rod mill outlet handling 7.5-to-29-millimeter rod and the bar-in-coil line handling 8-to-50-millimeter bar.

A New Technology for Increased Rolling Capacity

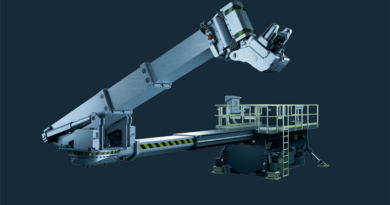

To reduce downtime, Primetals Technologies utilized four eDrive mini-finishing mills with 250 millimeter ultra heavy-duty roll housings for integrated single-family rolling from a standardized mill train. eDrive is one of Primetals Technologies’ newest long rolling solutions. Its purpose is to expand the already extensive capabilities of the company’s line of long rolling mill products by increasing load-carrying capacity, reducing long-term costs, enabling low temperature thermomechanical rolling, using quick-change roll units, and more.

The project scope included equipment supply, engineering, and site supervision services as an open consortium between Baowu Steel Group and Primetals Technologies. The full list of equipment included four eDrive mini-finishing mills, guide optics, a pinch roll and laying head, the latest high-speed pouring reels, as well as a mechatronics package comprising of the mechanical software necessary for this key equipment.

Dedicated Customer Support

In a letter of appreciation, Tang Jinsong, Director of Long Rolling at Baosteel, expressed his gratitude to Primetals Technologies saying, “During the commissioning period, we received the highly specialized technical support from Primetals Technologies’ site team including rolling process, fluids, and mechanical supervision personnel, as well as careful and personal service from the aftermarket service team. We are deeply satisfied with this and would like to express our sincere gratitude.”

“Primetals Technologies high-speed rod mill eDrive and bar-in-coil technology has been well received and the progress of the project has been highly praised by all parties.”Baoshan Iron and Steel, a subsidiary of Baowu Steel Group located in Shanghai, PRC, is a comprehensive steel service company specializing in the processing, sales, and technical services of stainless steel and carbon steel alloys, including high quality wire rod products since the late 1990s.