New metallic anchoring system incorporated within ceramic-fiber modules

Thermal conductivity of the overall metallic anchoring “system” incorporated within modules is very important factor. Except for module anchors that are fillet welded or stud welded to the vessel, most ceramic-fiber attachment systems use threaded components as an interface between the vessel casing and the internal hardware of the module.

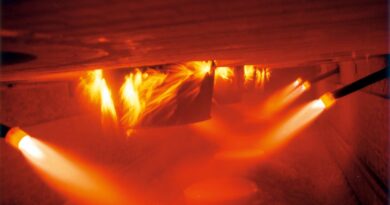

Eliminating heat-loss restrictions due to intermediate fasteners is a logical goal since heat-conduction pathways in threaded connections are minimal at best (Fig. below). A new patented welding method named the TiMig™ Fusion process can weld plate and other thin-gauge metals to steel vessels without the use of an intermediate fastener such as threaded components or mechanical clips. TiMig, unlike standard MIG welding, is a controlled-penetration weld that provides a direct path for heat to conduct to the steel casing through the weldment of a thin-gauge alloy yoke directly to the steel shell.