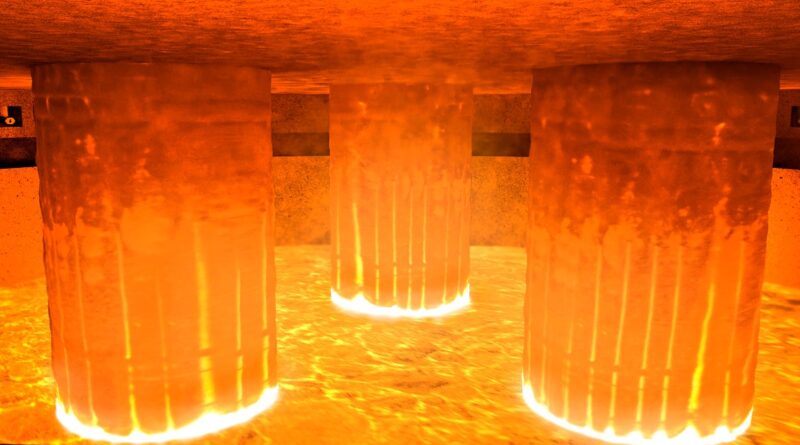

Next generation Fluid Bed Roaster for efficient roasting plant performance

Metso is launching the Next generation Fluid Bed Roaster, encompassing all the features developed and implemented in recent roaster projects executed globally. The Next generation Fluid Bed Roaster is a reactor with improved individual components and digital tools to enable more efficient and stable roasting plant performance.

“We are excited to launch the Next generation Fluid Bed Roaster. It is a logical progression in this digital age, combining advanced roaster equipment and enhancements as well as a suite of digital solutions for greater operational efficiency. The upgraded roaster is designed to adapt to operational changes, improving overall process control while ensuring safety, availability, and production KPIs,” explains Jörg Hammerschmidt, Director, Fluid Bed Technology at Metso.

Benefits of Metso’s Next generation Fluid Bed Roaster:

- Material that until recently was separated from roasting feeds can now be blended with the roaster feed after specific pre-treatment. This is particularly beneficial for extremely fine concentrates, by-products, and residues, as well as for material with a high content of low-melting impurities.

- The Next generation Fluid Bed Roaster increases plant safety, provides enhanced production stability in operation and reduces operating costs.

- The improved design and technical logic increase plant availability in the roasting area and hence availability of downstream plant sections, particularly the gas cleaning and sulfuric acid plant.

This is all achievable with high feed rates, efficient heat recovery, and other process performance improvements. Metso’s roasting solutions are based on decades of experience in developing processing technologies for concentrates and ores. Fluid bed roasting is a key pyrometallurgical technology, which allows the processing of a vast range of ores and concentrates. The next generation Fluid Bed Roaster is part of the Metso Plus offering.