OPTIMUS SINTER: a digital tool to improve sinter plant operations

Metso Outotec is launching Optimus Sinter, a digital optimizer for iron ore sintering plants. The new tool facilitates improved sinter plant process performance and stability by holistically optimizing the overall sintering processes.

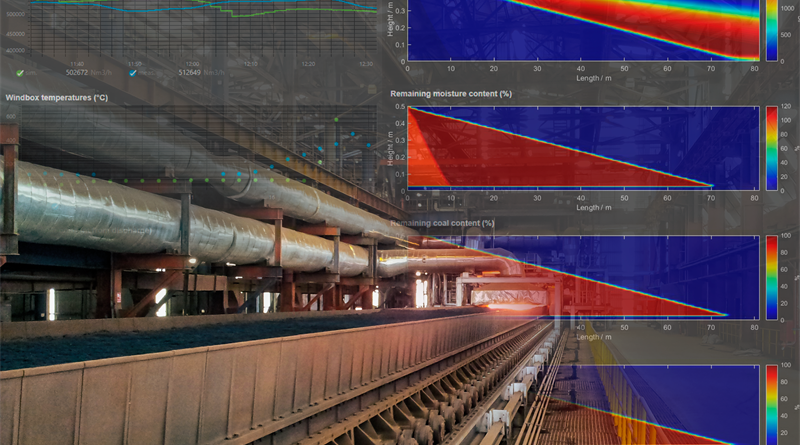

Optimus Sinter is one of Metso Outotec’s leading-edge digital solutions to ensure the optimal operation and maintenance of iron ore sintering plants. A sophisticated thermodynamic model forms the core of Metso Outotec’s Optimus Sinter; it calculates the process conditions in the sinter bed, which cannot be measured with sensors due to the high temperatures, and offers advanced insights into the sinter plant operations.

“We are very happy to announce the launch of our holistic sinter plant optimizer. With Optimus Sinter, our customers can get the best performance out of their operations. Operators can manage the plants better by leveraging the advanced insights this digital tool offers. Optimus Sinter also offers real-time operating advice with respect to different operating plant targets,” shares Andreas Meier-Hedde, Senior Product Manager for Sintering technology at Metso Outotec.

Backed by Metso Outotec’s decades of experience and process know-how in sintering, Optimus Sinter offers benefits such as increased gross production, improved electrical energy consumption and reduced solid fuel consumption. Based on process measurement and actual raw material data as well as the proprietary process model, Optimus Sinter provides:

- Online, real-time process calculations

- Monitoring of relevant process parameters and KPIs (energy consumption & CO2 footprint)

- Visualization of chemical and physical processes & temperatures in the sinter bed

- Online optimization of feed material mix

- Real-time forecast of product quality (sinter strength, Fe/Fe2+ content, basicity)

- Improved burn-through calculation