Revamping continuous pickling line for Kobe Steel

Primetals Technologies has received the final acceptance certificate (FAC) for revamping No. 2 continuous pickling line for Kakogawa Works of Kobe Steel, Ltd. An iBox replaced the existing pickling tank, and it demonstrated the improved productivity of high-strength strips for automobiles, saving of energy, and reduction of acid solution consumption in operation after the revamping work completion.

In the revamping work, a polypropylene iBox superior in chemical resistance and in retaining heat replaced the existing shallow tank consisting of acid-resistant bricks and steel plates, and acid solution storage tanks were added with incidental fittings.

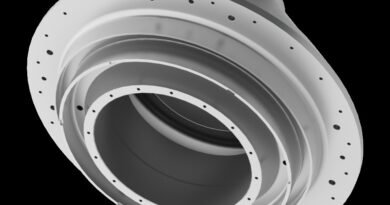

The iBox has immersion boxes inside through which strips travel guided by rolls and skids. This pickling process uses the strong shear flow generated by the narrow and rectangular channel the immersion boxes form to accelerate the acid-liquid reaction without an electric pump required to circulate the acid solution in conventional jet pickling tanks.

This is a continuous pickling line that pickles hot-rolled strips of 1.8 – 6 mm in thickness and 600 – 1,650 mm in width, at the maximum central speed of 240 m/min, and a maximum throughput of about 300 t/h.

Kobe Steel, Ltd. is a global company that operates on a worldwide scale under the group’s unified international brand of “KOBELCO.” It supplies high-value-added steel products, primarily long and flat products for automobiles, home appliances, ships, buildings, and bridge cables in Japan and overseas.

It is also involved in a wide range of other businesses, including other metal materials than steel, e.g. aluminum, titanium, copper and such, industrial machinery, e.g. compressors and isostatic pressurizers, construction machinery, and engineering.