Significant energy savings for Chanute Cement plant

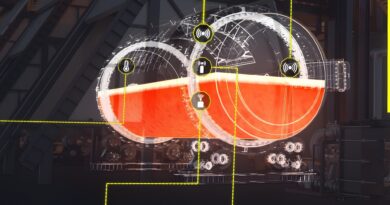

The newest version of FLSmidth’s high level, model-predictive control system – ECS/ProcessExpert® (PXP) was implemented on the Ash Grove Cement Company’s Chanute Plant cement kiln, a 4,650 stpd down-draft calciner with a 30-40% thermal substitution rate from alternative fuels. The PXP implementation started in June 2019 and was completed in August 2019.

PXP was implemented to accommodate Chanute Plant site-specific requirements involving plant personnel from process, maintenance, operations, instrumentation and quality teams.

According to the plant, PXP has provided a significant value to the operation since the commissioning. Some of the main benefits are:

- The automatic fuel compensation feature in ECS/PXP has helped stabilize the process when the Chanute Plant has waste fuel disturbances or a fuel substitution.

- By continuously monitoring all the primary parameters such as – kiln burning zone temperature (BZT), kiln amps, calciner temperature, O2, CO and free lime, the predictive changes made on the actuators, such as kiln feed rate, fuel consumption and ID fan speed, are continuous and very specific in the program’s decision making. With the decisions that PXP makes, the program positively impacts the kiln’s stability which results in consistent clinker quality and stable production rates.

- Monitoring the plant’s limitations, along with the primary parameters, is an added advantage. PXP changes the course of action based on parameters such as the ID fan exit pressure, bag house temperature and coal mill oxygen; these parameters directly affect the plant’s environmental compliance.

- Primary indications suggest that the Chanute plant can decrease its energy consumption by roughly 3.5% and decrease the standard deviation on the BZT, calciner temperature and cooler pressure by approximately 35%.