TOSYALI SULB orders Midrex with 2.5 million tons DRI complex

Libya intends to become a supplier of direct reduced iron (DRI) in the Mediterranean basin and beyond with the announcement of a DRI complex based on MIDREX Flex® technology to be built in the Benghazi region.

TOSYALI SULB Steel Industries, which was formed by TOSYALI and Libya United Steel Company for Iron & Steel Industry (SULB) to lead the development of the iron and steel sector in Libya, will immediately commence the first phase with construction of a 2.5-million-ton cold DRI (CDRI) plant.

TOSYALI SULB will utilize MIDREX® technology similar to what equips the two DRI plants owned and operated by TOSYALI Algerie in Bethioua (Oran), Algeria. With MIDREX Flex®, the plants can operate initially with natural gas and transition to using hydrogen, as it becomes available, making them leading contributors to green steel production. The Libyan plant will supply CDRI to meet the needs of the nearby region. When this investment is completed, TOSYALI SULB will be one of the key suppliers of DRI in the world.

Midrex Technologies, Inc.

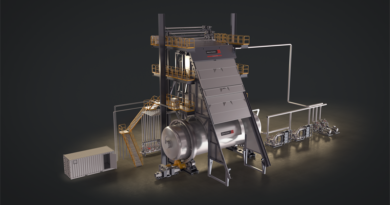

Midrex is the world leader in direct reduction ironmaking technology and aftermarket solutions for the steel industry. As developer of the MIDREX® Process, Midrex has designed, built, and serviced direct reduced iron (DRI) plants for 50-plus years. MIDREX Plants produce approximately 80 percent of the world’s low CO2 DRI. The MIDREX Process is highly flexible in reductant sources, iron oxide feed, and product discharge options.

Plants can be configured to operate on natural gas, natural gas with hydrogen addition (MIDREX Flex®), and 100 percent hydrogen (MIDREX H2™). Iron oxide pellets and lump ores, regardless of their Fe content, can be transformed into either cold DRI (CDRI), hot DRI (HDRI), or hot briquetted iron (HBI).

Plants can be designed for cold and hot discharge at the operator’s discretion, and proven options are available for transporting and charging HDRI into an EAF