Vertimill grinding technology for gold mine

Metso Outotec will deliver two energy-efficient Vertimill® VTM-4500 stirred mills to a gold mine in Australia 2021. These vertical grinding mills will be the largest of their kind to be installed in Australia. Typical value for this type of order is in the range of EUR 10 to 15 million, depending on the scope of delivery.

Vertimill provides the lowest total cost of ownership compared to other grinding mills in many applications thanks to its high energy efficiency, reduced media consumption, low installation cost as well as minimal liner wear and maintenance. It is capable of handling feed sizes up to 6mm and grinding to products less than 20 microns and it is available in standard mill sizes ranging from 15HP (11kW) to 4500HP (3352kW).

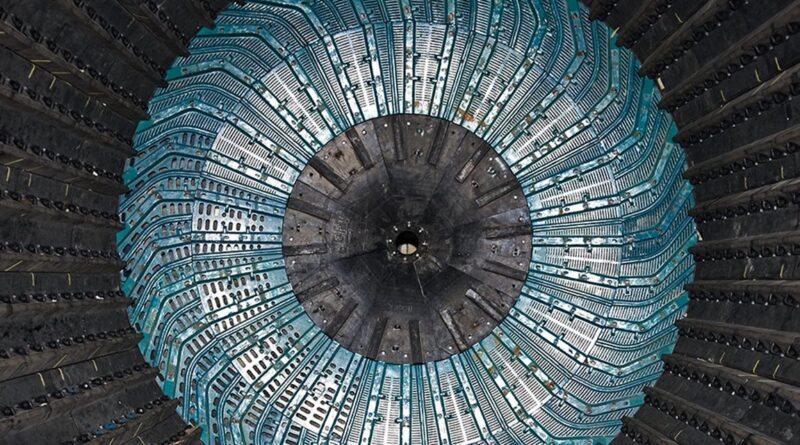

Mechanically, Vertimill® is a simple machine with an agitating screw suspended into the grinding chamber, supported by spherical roller bearings and driven by a fixed speed motor through a planetary gearbox.

The capacity of each unit size is relative to the required power input for the intended grind, however, mills have been operated with throughputs exceeding 500 mtph.

Vertimill® requires a simple and small foundation, which means less floor space is required. In fact, in the same application a Vertimill® has 50% less footprint than a ball mill.

Vertimill® is an energy-efficient grinding machine. They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns. This provides up to a 40% higher energy efficiency.