AUTHOR: Paul Hloben

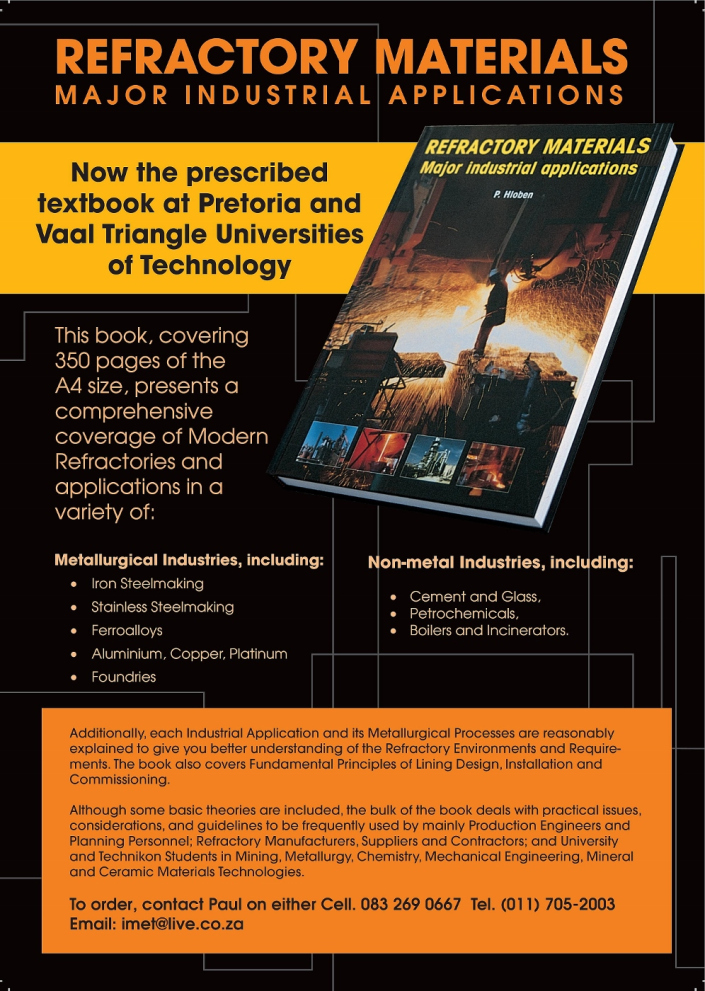

REFRACTORY MATERIALS

MAJOR INDUSTRIAL APPLICATIONS

ISBN 0-620-25867-5

The print editions are now sold out and we offer it as an eBOOK pdf file. That made it possible to bring down the price from R499 to R299 including VAT. the book will be sent to you by WE TRANSFER.com after receiving your payment. If you prefer to receive it on a memory stick, there will be a surcharge of R150 for the stick and couriered delivery.

This book has been sold worldwide; the first edition being printed in 2000 (hardcover) and the second edition in 2011 (softcover+updates).

Please email your order/inquiry to the address as per the advert below. For more info refer to the advert below.

CONTENTS

FOREWORD 6

EVOLUTION OF REFRACTORIES 7

Chapter 1: REFRACTORY PRINCIPLES 10

Classification of refractories10

The basic principle14

Properties and testing • 15

Standard properties16

High temperature properties18

Chemical properties22

Chapter 2: REFRACTORY MATERIALS 25

Manufacturing of refractory shapes25

Corundum materials29

Aluminosilicate raw materials31

Properties of aluminosilicate refractories 37

Aluminosilicate bricks42

Aluminosilicate monolithics45

Silica53

Silica products57

Basic refractories60

Magnesia60

Magnesia bricks66

Magnesia carbon66

Magnesia-chromite70

Magnesia-spinel73

Magnesia-forsterite75

Doloma (dolomite)76

Basic monolithics79

Zirconia and zircon80

Non-oxide refractories82

Carbon82

Silicon carbide85

Refractory metals87

Thermal insulation products90

Ceramic fibre products91

Chapter 3: DESIGN AND INSTALLATIONS 95

Refractory lining system95

Design95

Selection and quality of refractories97

Mechanical design99

Thermal design103

Insulating lining concept106

High conductivity lining concept107

Fibre lining design108

Suspended lining design111

Installation of refractory linings113

Installation of prefired shapes113

Installation of castables118

Installation of gunning materials123

Installation of plastics/mouldables125

Installation of ramming materials126

Anchorage127

Commissioning of refractory linings130

Chapter 4: IRONMAKING INDUSTRY 133

Coke ovens134

Refractory requirements for coke ovens 135

Blastfurnaces140

Refractory environments in blast furnaces 142

Lining concepts145

Refractory materials147

Blast furnace stoves151

Taphole clays for blast furnaces153

Troughs and runners for blast furnaces 154

Torpedo ladles156

The Corex furnace158

Direct reduced iron160

Chapter 5: STEELMAKING INDUSTRY 165

Steelmaking-overview165

Role of refractories in steelmaking167

Electric arc furnace172

EAF refractory linings174

EAF installation178

Maintenance179

Basic oxygen furnace181

Refractory requirements for BOF182

Wear mechanism183

Refractory linings185

Design186

Maintenance188

Installation190

Stainless (high-alloy) steel vessels193

Stainless steel plant193

Refractory linings195

Ladle metallurgy197

Casting ladles197

Purging plugs203

Sliding gates203

Ladle furnace207

RH Degasser207

Continuous casting210

Tundish linings211

Shrouds/Submerged entry nozzles214

Casting powders215

Reheating furnaces217

Wear mechanism219

Installation220

Maintenance221

Chapter 6: FERROALLOY INDUSTRY 222

Process furnaces222

Ferrochrome225

Ferromanganese and silicomanganese 227

Ferrosilicon and silicon metal229

Refractories for ferroalloys229

Refractories for rotary kilns231

Refractories for arc furnaces231

Refractories for ladles and moulds235

Refractories for converters236

Chapter 7: ALUMINIUM INDUSTRY 239

Primary aluminium239

Refractories for reduction cells240

Carbon baking furnaces243

Secondary aluminium246

Refractory requirements247

Reverberatory furnaces249

Chapter 8: COPPER INDUSTRY 253

Smelting stage254

Converting stage256

Refractory requirements258

Reverberatory furnace260

Flash smelting furnace261

Converter262

Anode refining furnace263

Chapter 9: PLATINUM INDUSTRY 266

Refractory requirements and wear mechanism 269

Refractory materials270

Six in line furnaces270

Pierce-Smith converters272

Chapter 10: FOUNDRIES 274

Foundry furnaces274

Refractory environments276

Refractory requirements278

Induction furnace linings279

Cupola furnace linings281

Arc furnace linings284

Resistant crucible furnaces285

Chapter 11: GLASS INDUSTRY 288

Glass furnaces288

Refractory requirements289

Melter290

Melter floor291

Melter tank blocks and ports292

Melter walls, crown and throat293

The refiner and foreheads294

Regenerator294

Chapter 12: CEMENT INDUSTRY 298

Cement kiln technology299

Wear mechanism300

Refractory requirements304

Rotary kiln305

Sintering zone refractories308

Preheaters and clinker coolers312

Installation and maintenance313

Curing, drying and heat up318

Preventive maintenance319

Chapter 13: PETROCHEMICAL INDUSTRY 321

Refractory requirements322

Installation325

FCCUs327

Carbon black329

Chapter 14: BOILERS (Power Generation and Incinerators) 331

Combustion process and refractories 331

Refractory requirements333

Boilers333

Incinerators334

Installation and repair337

GLOSSARY OF TERMS 340

BIBLIOGRAPHY 347

AUTHOR: Paul Hloben

REFRACTORY MATERIALS

MAJOR INDUSTRIAL APPLICATIONS

ISBN 0-620-25867-5

1st edition 2000

2nd edition 2011

Copyright © Paul Hloben 2000 – 2011

Published by Rexxon Corporation

TO ORDER PLEASE CONTACT

Cell/Mobil ++27 83 269 0667

E-mail: rexxonmedia@gmail.com

COPYRIGHT NOTICE

Except for normal review purposes, the book may not be reproduced in whole or in any part and in any form whatsoever without the prior permission of the publisher.

DISCLAIMER

The information provided in this book should not be used in relation to any specific industrial application without a thorough examination and investigation of the problem. The author and the publisher, therefore, do not accept any responsibility arising from such action.