Pushing the boundaries for low-carbon aluminium with Hydro CIRCAL

Hydro can now deliver Hydro CIRCAL recycled aluminium with a documented carbon footprint of 1.9 kg of CO2e/kg aluminium, down from previous 2.3 kg of CO2e/kg. This is done through advances in sourcing, sorting and traceability of post-consumer aluminium scrap.

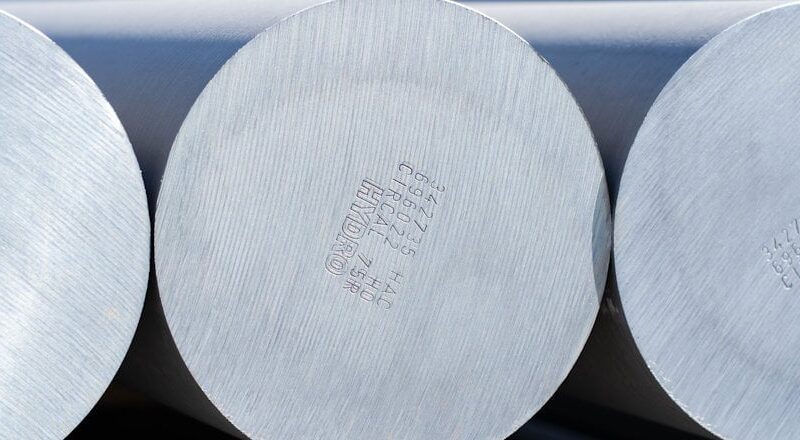

Hydro CIRCAL was originally launched in 2019. It is a prime quality, recycled aluminium made with a minimum of 75 percent recycled post-consumer scrap, certified by an independent third party (DNV). Hydro currently produces Hydro CIRCAL at its plants in Clervaux, Luxembourg, Azuqueca, Spain, and Wrexham, UK, as well as three recyclers in the U.S. The recently updated Environmental Product Declaration (EPD) covers the European recyclers and documents an average embodied footprint from the Hydro CIRCAL production of only 1.9 kg of CO2e/kg of aluminium, down from the previous 2.3 kg of CO2e/kg of aluminium.

“Hydro has been pushing the boundaries for low-carbon aluminium with Hydro CIRCAL. We are very proud to deliver a brand with a market leading footprint across the value chain from scrap to final product. In a fairly short time, Hydro CIRCAL has become a key part of our product portfolio. With the new EPD, we continue to deliver aluminium with a carbon footprint that will enable our most forward leaning and demanding customers to deliver on their climate targets,” says Ingrid Guddal, Head of Recycling in Hydro Aluminium Metal.

Hydro CIRCAL is part of Hydro’s range of premium low-carbon aluminium. Hydro is constantly pushing the boundaries of low-carbon aluminium by pursuing initiatives to decarbonize the company’s processes through increased use of cleaner energy or new technology development. Hydro’s focus on decarbonization across the value chain allows Hydro to offer premium products to selected strategic partners, such as Hydro REDUXA 3.0, which is key for the partnership with Mercedes-Benz.

“In early 2023, we also delivered the first near-zero carbon footprint aluminium for the European building and construction market based on Hydro CIRCAL, with 100 percent post-consumer scrap content,” says Guddal.

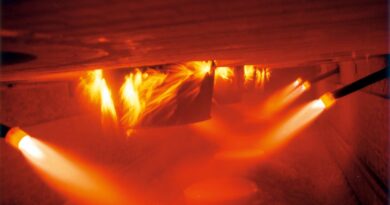

Hydro has an extensive recycling network, with a total of 30 recycling facilities in Europe, North America and Brazil. Growth in recycling is a central part of Hydro’s strategy, and the company is stepping up its growth ambitions to meet the increasing demand for low-carbon, recycled products. With a focus on increased use of post-consumer scrap, Hydro aims to further diversify the portfolio of cast house products, in collaboration with customers, to unlock the potential for increased use of recycled materials for a more circular economy.