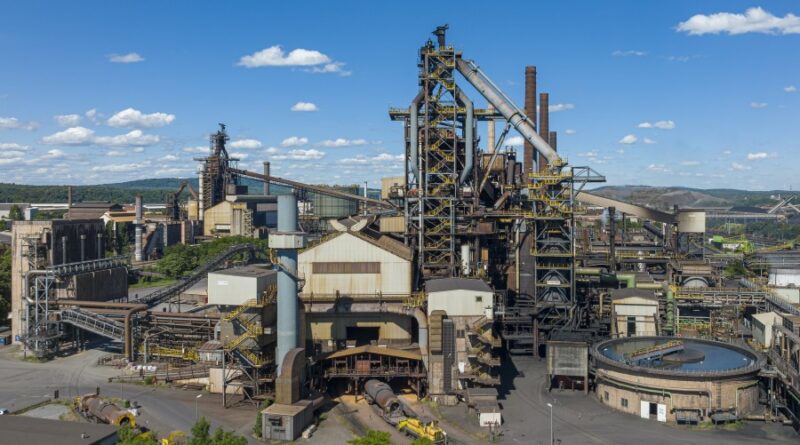

Durability and wear monitoring of blast furnace 4 at ROGESA

Durability and wear monitoring of blast furnace 4 at ROGESA ROGESA Roheisengesellschaft Saar GmbH in Dillingen, Germany has commissioned SMS group to carry out a comprehensive modernization of blast furnace 4 (BF4), which will extend the service life of the blast furnace and ensure effective monitoring of the hearth lining.

The contract includes the planning and delivery of the Paul Wurth hearth lining and multi thermocouple sensor probes (MTPs), as well as technical support during the installation phase.The required upgrade is based on measurements taken in 2023, which indicated that the wear on the hearth of blast furnace 4 is more advanced than expected, and that the remaining wall thickness is approaching the wear limit.

Blast furnace 4, built in the late 1970s, was enlarged and relined by Paul Wurth in 2003. It has a usable volume of 2,460 cubic meters and an output of 6,400 tons per day. The last reline on blast furnace 4 took place in 2016.For the new furnace lining, SMS plans to use Paul Wurth hearth lining technology, including carbon blocks, ceramic cups, and refractory materials, which are known for their durability and reliability.

Well-designed equipment offers exceptional thermal insulation by maintaining the extremely high temperatures required for iron ore reduction. In addition, it offers corrosion resistance by avoiding chemical attacks from molten iron and slag, and structural support by withstanding mechanical stresses and maintaining the furnace’s shape.

The multi thermocouple sensor probes are designed to precisely determine and track hearth lining wear, thereby ensuring enhanced monitoring and operational efficiency.The project is expected to be completed in the third quarter of 2025, with a shutdown time of only 55 days.This project underscores the long-standing and trustful relationship between SMS group and ROGESA. Previous collaborations have focused on hot blast stoves and refractory-related projects.