Guinea’s bauxite processed in new UAE alumina refinery

Emirates Global Aluminium, the largest industrial company in the United Arab Emirates outside oil and gas, today announced that production at its new Al Taweelah alumina refinery achieved nameplate capacity from bauxite to alumina for June, a major milestone in the ramp-up of the giant plant.

The milestone was achieved just 14 months after alumina production began in April last year, a world-class performance. The milestone was achieved safely, with zero injuries leading to time off work.

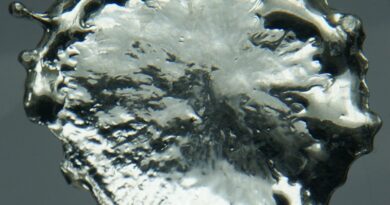

Alumina refineries convert bauxite to alumina in a four-step process which in parts exceeds 1000˚C and 100 times atmospheric pressure. It can take several years or more for new alumina refineries to reach a month of sustained production at design capacity at each step of the process.

Zaher Alhabtari, Executive Vice President Upstream and Capital Projects at EGA, said today: “We began preparing for operations back in October 2013, when Al Taweelah alumina refinery was still on the drawing board.

Our careful planning has enabled us to deliver a world-class ramp-up of this important project and I congratulate every member of the team for their contribution to this benchmark achievement. We are now focused on the next milestone, which is three consecutive months of production at nameplate capacity.”

Al Taweelah alumina refinery cost some $3.3 billion to build, and is the first alumina refinery in the UAE. Alumina is the feedstock for aluminium smelters.

The nameplate capacity of the plant is some 2 million tonnes of alumina per year, enough to meet 40 per cent of EGA’s alumina needs and replacing some imports.

The development of Al Taweelah alumina refinery was part of EGA’s strategic expansion upstream in the aluminium value chain, making EGA an integrated global aluminium giant. EGA began production at its bauxite mining and export subsidiary, Guinea Alumina Corporation, in August last year.

Some 589 people work at Al Taweelah alumina refinery, including alumina refining experts recruited from countries from Jamaica to Australia.

To develop local capacity in a new industrial activity for the UAE, EGA began training UAE Nationals for roles at Al Taweelah alumina refinery at the project’s inception. This included secondments to an operating alumina refinery in Saudi Arabia.

Today some 66 UAE Nationals work at Al Taweelah alumina refinery, including 37 women.

The development of Al Taweelah alumina refinery has created opportunities for other industries in the supply chain, including shipping and trade.

EGA is importing bauxite for the project using Capesize vessels, which are amongst the world’s largest. EGA’s long-term requirement to bring these ships to its berth at Khalifa Port enabled Abu Dhabi Ports to invest in deepening the approaches, making it the first port in the Gulf able to handle ships of this size including container vessels.