GKN PM identifies potential of DP 600 steel

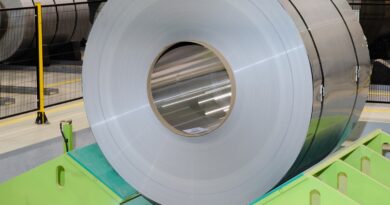

As the IDAM project nears its halfway mark, one of the most notable advancements is the identification of a metal powder material by GKN Powder Metallurgy (GKN PM) that demonstrates excellent potential for industrialization in the automotive market. The material is DP 600, a dual-phase steel whose mechanical properties can be tuned using heat treatment methods.

The gas atomized material, which is now being validated on the EOS M300-4 system, demonstrates an elongation rate of 13% (as-built) up to 22% (with heat treatment), and a tensile strength of 950 MPA (as-built) up to 700 MPA (with heat treatment).

These tunable properties make the dual-phase steel material a good candidate for several structural automotive applications, as well as for other applications in the industrial market. Further potential to reduce cost per part can be achieved by using water atomized powders for future applications.

In March 2019, a consortium of 12 partners from across the additive manufacturing, automotive, research and industrial sectors launched the Industrialization and Digitalization of Additive Manufacturing (IDAM) project.

At its core, the project addresses the limitations of laser powder bed fusion (LPBF) AM, including the lack of automation and high associated costs that hinder the technology’s adoption for industrial, serial production in industries such as automotive.

The 20 million euro initiative is partially funded by the German Federal Ministry of Education and Research (BMBF), and brings together 12 partners: GKN Powder Metallurgy, BMW Group, Aconity GmbH, Concept Reply GmbH, Myrenne GmbH, Intec GmbH, Kinexon Industries GmbH, Volkmann GmbH, Schmitz Spezialmaschinenbau GmbH, Chair for Digital Additive Production DAP, Fraunhofer Institute for Laser Technology ILT and Technical University of Munich, Chair of Metal Forming and Casting.

Each partner contributes in its specific area of expertise to help establish a pilot line for a fully automated, industrial-ready additive production. The goal of IDAM is to build two pilot lines—one at GKN PM’s factory in Bonn, and the other at BMW Group’s facility in Munich—to demonstrate a digitalized and IoT-driven production line for 3D printing automotive components.

When these pilot lines are up and running, the IDAM consortium aims to produce over 10,000 individual and spare parts per year, as well as at least 50,000 mass-produced components.

GKN Powder Metallurgy is shaping the future through powder metallurgy with more than 13 million parts produced daily. The company provides leading powder metal expertise and process experience to transform ideas into production.

GKN Powder Metallurgy combines three focused business under one brand, consisting of GKN Hoeganaes, GKN Sinter Metals, and GKN Additive to provide material development, conventional powder metal components, and plastic and metal 3D printing.

Together GKN Powder Metallurgy empowers over 6,400 problem solvers in 29 locations, setting its global engineering network at the highest standard.