Vertical pressure filter for solids removal in aluminate solutions

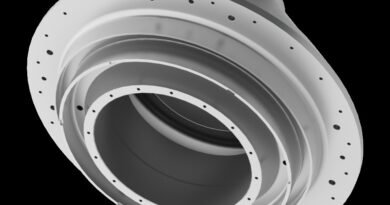

Metso Outotec is introducing the higher capacity Vertical Pressure Filter (VPF) for optimized solids removal in aluminate solutions. The VPF optimizes the removal of suspended solids before alumina hydrate precipitation, reducing entrained particulate concentrations in sodium aluminate solutions to a level of only a few milligrams per liter.

“Filtration of supersaturated aluminate liquor is a vital step in the production cycle to meet the required quality standards for smelter grade alumina (SGA). The VPF is based on proven technology that provides superior solids removal along with easy and safe operation. The VPF nicely complements our wide offering in alumina technology,” says Senior Product Manager, Metals & Chemical Processing.

The VPF’s design features improve sustainability and overall process performance and decrease costs. The automatic cloth cleaning and cake discharge steps at the end of each filtration cycle ensure maximum filtration time in subsequent cycles. The VPF includes sequence control for multiple filters and can be fully integrated with the plant’s automation system.

Thanks to its smart design, the VPF is safe and cost efficient to operate and maintain. The filter vessel remains securely closed and sealed during filtration, cloth cleaning, and cake discharge, and has easy access for inspection and maintenance. Filter leaves can be easily replaced as single units with the use of an overhead crane.

The compact design of the filter minimizes the space needed and therefore reduces the associated construction costs. Downtime needs for cloth cleaning and cake discharge are minimized, thanks to the extended filtration cycle of up to 18 hours. In addition, the efficient cloth cleaning system maximizes cloth lifetime. The filter doesn’t have any moving parts, so maintenance cost per cubic meter of produced filtrate and wear part consumption is low.