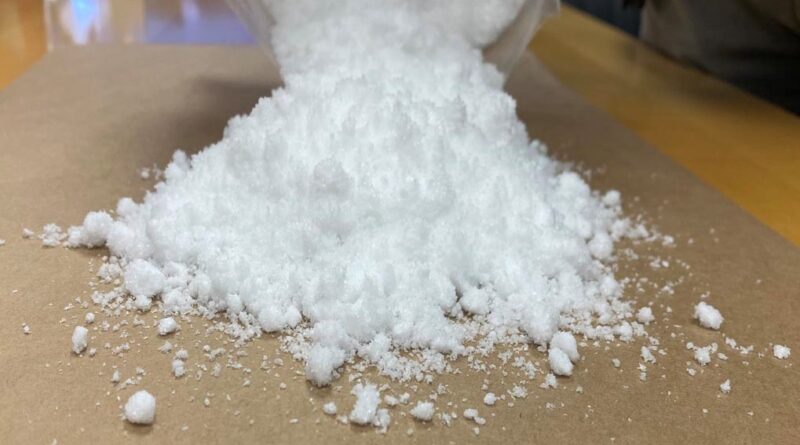

American Manganese produces 99.99% lithium sulfate

American Manganese has reported the successful production of lithium sulfate (Li2SO4) with 99.99% purity. The bulk sample of lithium sulfatewas prepared and sent to an international lithium producer to validate the patented RecycLiCo process.

”We are extremely pleased with the production of 99.99% pure lithium sulfate directly from the most valuable and least environmentally disruptive source of lithium available in the world – which in my opinion is the end-of-life battery,” commented Larry Reaugh, President and CEO of American Manganese. “To produce green batteries, you need ‘green’ lithium, and we are thrilled to be engaged with companies that recognize the promise of RecycLiCo. We are confident that our product will align with the lithium-ion battery industry’s needs, and which will unlock long-term environmental benefits.”

The RecycLiCo process first leached lithium-ion battery cathode scrap and black mass material with an extraction efficiency of over 99%. The resulting pregnant leach solution is then coprecipitated to produce cathode precursor material (nickel, cobalt, and manganese). The remaining solution subsequently undergoes separate extraction of high purity lithium sulfate while regenerating process chemicals for the closed-loop process. Together, the cathode precursor and lithium sulfate product accounts for most of the lithium-ion battery’s material value and can be re-integrated into new battery manufacturing.

Throughout American Manganese’s R&D and pilot plant project, the Company successfully produced other lithium derivatives such as lithium hydroxide and lithium carbonate, enabling a robust RecycLiCo process that can adapt to the changing needs of the lithium-ion battery industry.

American Manganese Inc. is a critical minerals company focused on the upcycling of lithium-ion battery waste into high-value battery cathode materials, using its closed-loop RecycLiCo process. With minimal processing steps and up to 99% extraction of lithium, cobalt, nickel, and manganese, the upcycling process creates valuable lithium-ion battery materials for direct integration into the re-manufacturing of new lithium-ion batteries.