Coating innovation – the new fast dry water based coating

Almost all foundries supplying the automotive industry have now switched to the use of water based coatings. This is state of the art.

However, when larger castings are produced in small batches or even single parts, the use of water based coating is not really popular. The reasons for this include the following:

- the lack of drying and storage capacity

- the loss of time due to longer drying times and

- thus the lower productivity.

On the other hand, the demand for safe, less VOC-releasing and more cost-effective products has never been greater, especially in the jobbing casting segment. Added to this is the current shortage of ethanol and isopropanol solvents due to the corona crisis.

Many foundries are currently paying many times more for solvent coatings in order to maintain production. In addition, the quality is often inferior and there is still uncertainty about availability.

Therefore, the ultimate solution for use in steel and iron customer foundries in this case is a coating that is harmless to health and dries independently in a short time, a coating that provides the same or better casting surface finish and also is not subject to hazardous material storage regulations.

The range of our new SEMCO FD waterbased fast dry coatings includes:

- Pure zircon based filler formulations for the heaviest iron and steel applications

- Aluminum silicate types for iron and smaller steel castings and

- a range of other silicate fillers to optimize cost and application

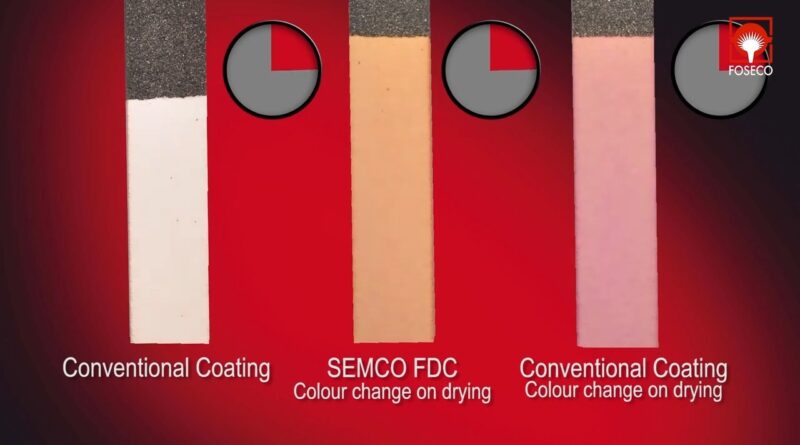

To address these needs, Foseco has developed a new fast drying water based coating called SEMCO FD.

The concept of SEMCO FD is unique in that it allows foundries to use coatings with significantly higher solids content, which provides greater protection against casting defects.

The result is an accelerated drying process, lower energy consumption, an enormous improvement in the quality of the working environment, as well as improved profitability of the foundry.