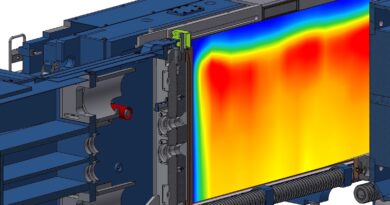

AMETEK Land pyrometers detect radiation emitted by target surface

Accurate temperature measurements are essential on a variety of production/processing lines, including annealing, galvanising, coating, and electrical/silicon steel processing lines, to ensure high product quality and to optimise process efficiency.

Modern continuous annealing lines (CAL) perform high-speed processing on steel strips. The annealing and heat treatment process requires the steel strip to be taken through a tightly controlled heating and cooling temperature profile, which is critical to achieving the desired properties of new, advanced, high-strength steels (AHSS). Therefore, accurate temperature measurement at each zone is essential for process and quality control.

With 75 years’ experience in supplying the world’s steel manufacturers, AMETEK Land has extensive application expertise and technology to deliver reliable temperature monitoring and control for CAL / CGL coating applications.

It offers a range of advanced infrared non-contact pyrometers to overcome the challenges of changing emissivity and high background temperatures.

The SPOT Smart Pyrometer Series is a family of fully featured, high-performance pyrometers for fixed non-contact infrared spot temperature measurements. It is available in a range of operating wavelengths, temperature ranges, and process requirements.

The advanced SPOT GS application pyrometer is designed for automated furnace management, close control of the galvannealing reaction as well as the coating solidification. It is designed for continuous, highly accurate temperature measurement of coated steel strip during galvanising, galvannealing, silicon and electrical steel processing.

Installed at a distance, pyrometers detect the infrared radiation that is emitted by the target surface. Their non-contact operation allows them to operate out of harm’s way, and, because they do not touch the surface, they can accurately measure moving objects without damaging them.

Pyrometers also feature extremely fast response speeds, within milliseconds, which makes them very useful for measuring fast-moving strip or rod. Reflective strip surfaces and high background temperatures make the CAL / CGL lines a challenging environment for optical measurements.

They are the recommended solution for the most accurate and reliable measurements in furnace and coating processes.