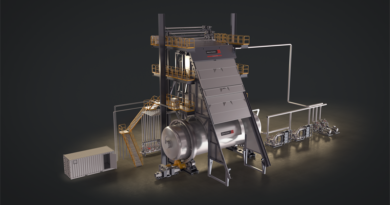

Billet caster for SBQ production at Henan Jiyuan Iron @ Steel Company

Henan Jiyuan Iron and Steel (Group) Co., Ltd in China has awarded SMS Concast the order to modernize its eight-strand continuous caster CCM#2, which was originally supplied by a local manufacturer, at its Jiyuan plant no. 2.

The modernization project aims to improve product quality and productivity while increasing the flexibility in processing different steel grades to achieve an annual billet production capacity of more than 1,000,000 tons. With eight strands and a ten-meter nominal radius, the machine is equipped to cast three section sizes: 150 millimeters square, 160 millimeters square, and 180 millimeters square. More than 90 percent of the product mix will include high-carbon grades such as bearing and spring steels and a full range of steel grades for the automotive industry.

The upgrade, to be undertaken entirely by SMS, covers a comprehensive redesign of CCM#2, making it one of the most modern casting installations worldwide and featuring Dynamic Mechanical Soft Reduction, among other highlights, to improve the inner quality of the billets by precisely controlling the central porosity and segregation.

In addition to the Dynamic Mechanical Soft Reduction (DMSR) feature, the implementation of which is quite a challenge in view of the low strand spacing of only 1,200 millimeters, the modernization project includes a range of other technological solutions. For example, the CONFLOW® Stopper Technology, which ensures precise control of the steel flow to the mold, a compact oscillation system with CONDRIVE®, which allows a range of oscillation parameters to be chosen using an electromechanical system, the air-mist spray cooling unit, and, finally, our well-established deburring technology. Not only that, a number of existing systems will also be carefully integrated into the new caster design.

The billet quality assurance is controlled by a level 2 quality control system featuring ‘slice by slice’ identification, a computerized billet tracking system, heat extraction mode, optimized rest length calculation model, and equipment lifetime recording.