Building domestic clinker production in Nepal

After years relying on clinker imports, the Nepalese cement industry is now seeing rapid expansion of its domestic clinker production capacity. Among those building new production facilities is Palpa Cement Industries Pvt Ltd, who have recently installed a new state-of-the-art FLSmidth clinker production line.

The Nepalese cement industry has traditionally been reliant on clinker imports from India to supply local grinding plants. But this is changing. The Nepalese government is imposing duties on clinker imports and encouraging cement producers to set up clinker production lines. Palpa Cement has been one of those to respond, setting up its own clinker manufacturing unit in Sunwal.

To make the most of the opportunity, Palpa Cement required a plant with low CAPEX but that still offered state-of-the-art technology from a proven supplier, as well as high efficiency in terms of fuel and energy consumption.

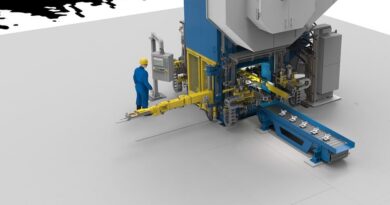

After a competitive bidding process, the company awarded us the contract for the complete production line, including stacker/reclaimer, vertical roller mills for raw and coal grinding, pyroprocessing line, electrical distribution systems and plant control system.

Responding to the customer’s requirements, “we were able to eliminate the raw mill cyclone building by placing the cyclones above the raw meal silo, which was moved closer to the ground, while the kiln feed bin, usually found below the raw meal silo, was moved to the pre-heater platform. This avoided the need for additional cyclone support structures and for additional equipment like the silo feed bucket elevator, airslide conveyers, and blowers. As a result, the plant layout is the most compact in Nepal for its size,” said Mr. P.N.Bansal, Plant Head, Palpa Cement Industries

The compact plant arrangement was not the only first for Nepal. The customer also required a longer calciner and bigger cyclones for the preheater to accommodate 100% petcoke / any alternative fuel. A slewing stacker in order to stack one side of the stockyard with limestone and the other with fuel – a unique feature for this type of plant.

As a one-source supplier to the cement industry, we were able to respond to Palpa Cement’s needs and offer in-house solutions. Palpa Cement’s promoters visited two other Nepalese cement producers to see our technology in the real world. Both companies have FLSmidth-supplied clinker lines and cement grinding units.