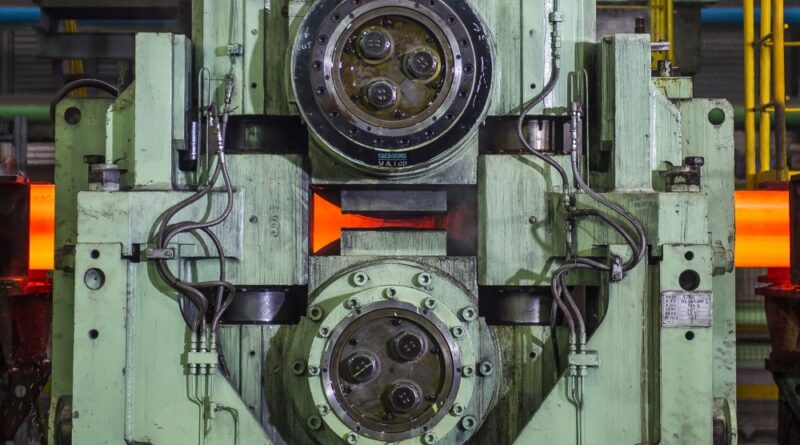

CMC Poland to revamp the rolling mill in Zawiercie.

The mill produces 500,000 tpy of bars and wirerod for construction, agricultural, energy, machinery, and consumer goods applications.

The purpose of the revamping is to optimize rolling performances, as well as to update the mill hardware for increased plant availability.

New, low-voltage inverter drives for the mill’s roughing and intermediate sections will be installed to improve operation and plant maintainability.

Special attention will be paid to the reheating furnace heating-up billets produced by the local meltshop to accurate rolling temperatures. There, hardware and software for Level 1 automation system will be upgraded. A new process control system for automatic set up of the heating curves of the furnace also will be supplied.

The upgrade will be executed by the end of this year.