Conversion of wide hot-strip mill to increase production

Panzhihua Steel & Vanadium Co. Ltd., China, has ordered an extensive modernization of their 1,450-millimeter hot strip mill (HSM) in Panzhihua, Sichuan Province. With this comprehensive revamping of the mill, in operation since 1996, Panzhihua intends to significantly improve plant availability, increase the production capacity, and expand the production range to include thin-gauge strip.

The annual production capacity will be raised from currently 2.4 million tons to at least 3 million tons. The revamping will further enhance the flexibility of the HSM with regard to the product mix, which includes carbon steels as well as silicon steels and titanium strips.

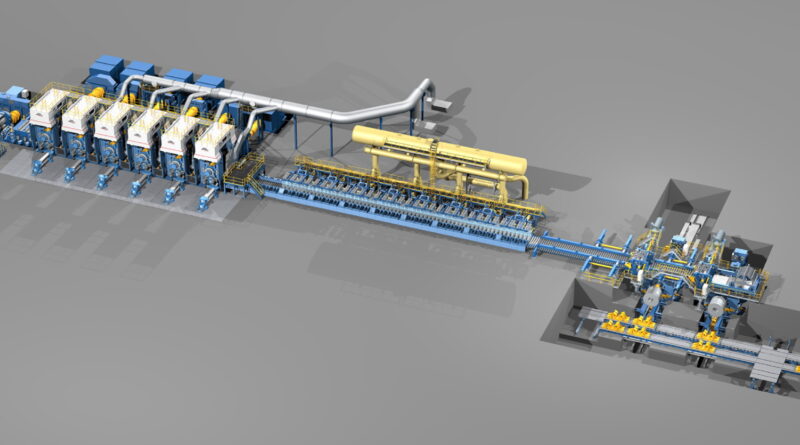

A new seven-stand finishing mill will be erected behind the existing finishing mill. The new mill stands will be equipped with hydraulic screwdown systems, hydraulic loopers and CVCplus shifting and bending systems (Continuously Variable Crown).

The design of the laminar cooling line will provide very high flexibility in terms of cooling rates and cooling patterns enabling Panzhihua to produce highly demanding modern steel grades and be prepared for future demands. Flow meters for process control will assure high repeatability of operation to meet the highest quality standards.

Also the coiler area consisting of two downcoilers will be completely replaced, including the related side guiding systems. The first hot strip is scheduled to be rolled in October 2022.

With this revamp – which entails the renewal of all quality-relevant equipment – Panzhihua Steel & Vanadium will expand their product mix to include thin-gauge and high-strength hot strips, while increasing the availability of the mill and, as a result, its production capacity.