Dillinger improves blast furnace cooling with cast iron staves

Dillinger has placed an order with SMS group for new Paul Wurth cast iron staves and a number of copper staves for blast furnace 5, which has an annual production volume of around 2.5 million tons of hot metal. The equipment package is designed to replace existing copper staves and is perfectly aligned with Dillinger’s strategic objective of achieving an extended blast furnace campaign.

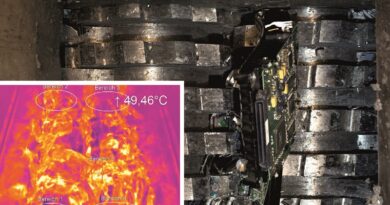

Cast iron staves are used in the upper furnace areas, where they provide efficient and durable furnace cooling, protect the blast furnace shell against thermal loads, and optimize production efficiency.

The use of cast iron staves was primarily chosen to align initial capital expenditure with the anticipated system service life. The existing Paul Wurth copper stave lining, installed in 2010, delivered a service life of 16 years. The newly manufactured Paul Wurth cast iron staves meet the customer’s requirements in every respect.

“We appreciate Dillingen’s continued trust and the long-standing working relationship. Moving predominantly to cast iron staves is a pragmatic decision to balance lifecycle needs and budgetary constraints. Our team is focused on delivering the agreed scope on schedule and supporting a smooth installation during the planned summer 2026 shutdown,” said Lutwin Franziskus, SMS project manager.