E-waste needs to be recycled for platinum and other metals

On October 14, the third International E-Waste Day is being held; this year, a particular focus will be given to education about the ways to tackle the growing e-waste problem. E-waste, or “electronic and electrical waste,” is electronic products that are nearing the end of their useful life and are discarded.

Computers, televisions, VCRs, stereos, copiers and fax machines are common electronic waste that can be reused, refurbished or even recycled. E-waste is particularly dangerous due to toxic chemicals that are released when the appliance is buried.

The ongoing debate as to how to most effectively dispose of used and unwanted electronics has become a major issue especially with the growing amount of e-waste. Due to rapid technological advances, many electronic devices that still function are considered obsolete, which leads to excessive debris of e-waste found in landfills.

International E-Waste Day is used to highlight to consumers the importance of repairing or correctly disposing of used appliances with the aim to increase re-use, repair, recovery and recycling.

E-waste and Toxic Materials

Most electronic products contain toxic metals such as beryllium, cadmium, mercury and lead which are serious threats to soil, water, air and wildlife.

More specifically, when E-waste gets buried at a landfill, the toxic materials dissolve into a sludge that permeates at the bottom of a landfill. These traces of toxic materials then sink into the ground below the landfill. This process is known as leaching.

In 2019, the world produced a record 59 million metric tons of e-waste, up from 48.5 million tons in 2018, according to a UN report. Out of this, less than 20% is recycled. At this rate, the UN estimates that we could reach 120 million tons of electronic scrap by 2050. This volume of e-waste will present detrimental threats to the environment polluting rivers, lakes and seas, and also release toxic gases into the atmosphere.

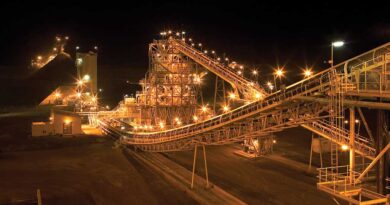

According to a report published in 2019, it is 13 times more costly to extract minerals from natural deposits than it is to recover them from technological waste for the manufacturing of new devices. Obtaining minerals like platinum, copper and palladium is a rigorous process requiring huge quantities of water and energy. Recycling technological waste would be beneficial for further manufacturing of new electronic gadgets.

With the endless production of e-waste, many countries have recognised the need for proper recycling processes and are working on implementing sustainable solutions.

Besides the EU, some countries are creating their own legal frameworks to anticipate and prevent planned obsolescence. International cooperation and associations are supporting this progress in order to facilitate sustainable and global recycling chains.