Govt’s infrastructure plans to boost demand for galvanized steel

PRETORIA – Government spending on building new and rehabilitating existing infrastructure will increase from R66.7 billion from 2022 to 2023 to R112.5 billion from 2025 to 2026. It includes roads, bridges, stormwater systems and public buildings. This makes spending on capital assets the fastest growing item by economic classification.

This will improve public service provision and address backlogs and boost increased investment, growth and employment potential, according to Finance Minister Enoch Godongwana in his 2022 Medium Term Budget Policy Statement on 26 October 2022.

“We are also committed to improving state capacity, project planning and preparation, procurement practices, and contract management. This will address chronic underspending of allocated infrastructure budgets, improve value for money and efficacy of our investments,” said Minister Godongwana.

The government’s commitment to increased infrastructure spend is likely to result in a dramatically increased uptake in the local consumption of zinc galvanized steel, says International Zinc Association (IZA) Africa Executive Director Simon Norton. The focus on renewable energy to meet the country’s electricity shortfall will also lead to a boom in solar energy plants and wind farms, which present another avenue for the increased uptake of zinc-coated steel.

While South Africa has 20% of the world’s zinc deposits, it no longer refines any zinc following the closure of the Zincor refinery in Springs by mining company Exxaro at the end of 2011. Up to that point, the country produced 110 000 t/y of refined zinc worth about R4.3 billion. From 2014 to 2019, South Africa imported R15 billion worth of refined zinc.

However, the uptake of refined zinc declined from 119 000 t in 2011 to 72 000 t in 2021. “Zinc is one of the major global commodities, along with iron ore, for example. IZA Africa’s short-term goal is to gradually boost zinc uptake to a new high of 90 000 t/y, ultimately reaching 100 000 t/y in three years’ time,” highlights Norton.

Zinc truly comes into its own in offering long-lasting corrosion protection, an important consideration at South Africa’s corrosive coastal zones. As a barrier protection, zinc resists corrosion by isolating steel from the external environment. Zinc is also anodic to steel, meaning it corrodes sacrificially to protect the underlying steel.

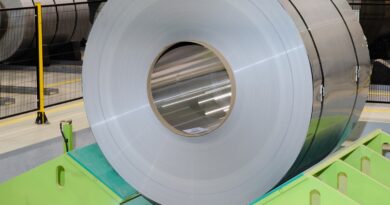

In addition, a natural zinc patina develops as the zinc coating weathers, slowing the overall corrosion rate, as well as creating a material with a distinctive appearance that is much in demand by architects and designers. Such a coating is applied by the process of either hot dip galvanizing or continuous galvanizing, the latter used mainly for steel sheet, wire and rod. IZA Africa promotes awareness of the corrosion protection capability of zinc among professionals such as engineering designers, civil and consulting engineers. It also encourages South African zinc industry companies such as hot dip galvanizers, continuous galvanizers, wire plants and die casters to become members of