Hydrogen as a replacement fuel in steelmaking and alumina refining

In iron and steel production, 93% of emissions originate from the smelting process, which includes the use of blast furnaces, coking, and sinter plants.

In refinery operations, steelmaking, and the use of casting plants account for another 5% of emissions. Overall, the carbon impact of steelmaking represents a significant 92% of emissions, largely from burning carbon-rich fuels.

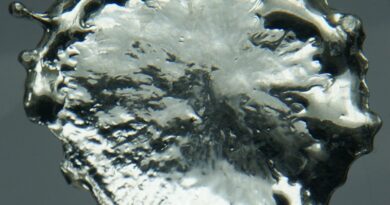

The use of hydrogen as a replacement for blast furnaces has been investigated extensively. Research suggests that the fuel can act as a cleaner, making it an effective alternative to coal and coke due to its capabilities of reducing carbon in the direct reduction of iron (DRI) process.

The research finds that 78% of aluminium value chain emissions arise from the smelting process, the casthouse and electrolysis. The electrolysis emissions that arise from the reduction process ranges from 0 to 14 tonnes of CO2e/tonne of aluminium.

Breaking down the aluminium refining process further, 70% of emissions arise from steam during digestion and 30% comes from fossil fuel combustion in calcination.

Norwegian aluminium company Hydro has been conducting experiments at its Navarra plant, and has found that hydrogen could act as a replacement for natural gas at cast houses and in digestion processes.

Similarly, the Anglo-Australian mining group Rio Tinto and Japan’s Sumitomo corporation are currently working on a proposal for the construction of a hydrogen pilot plant that will trial lower-carbon alumina refining. The initiative will use a 2.5MW electrolyser with a production capacity of more than 250 tonnes of hydrogen annually, which could pave the way for hydrogen adoption across the industry.