HYDROGEN: Toward a carbon-neutral steelmaking

Recently, ArcelorMittal and Midrex have teamed up to use hydrogen on an industrial scale as the reductant for producing direct reduced iron (DRI). The mutual project will utilize hydrogen generated by the existing MIDREX Plant at ArcelorMittal Hamburg.

The project will further our understanding of how DRI plants could take advantage of green hydrogen generated from renewable sources and help move closer to a carbon-neutral steel industry.

Although high percentages of hydrogen have been used in operational MIDREX Plants, there are still things to be learned about using pure hydrogen, which can be studied only when the process configuration is run on a large scale.

Midrex and ArcelorMittal have signed two agreements: a Framework Cooperation Agreement (FCA) and a Project Development Agreement (PDA). The FCA allows the companies to cooperate on the current hydrogen project and future development efforts.

This agreement envisions the parties working together on projects through individual PDAs. The first PDA deals with designing and constructing a demonstration plant utilizing the hydrogen from the existing MIDREX Plant.

This project will allow the companies to demonstrate the production of DRI with hydrogen, as well as to utilize carbon-free DRI in the EAF at an industrial scale. It will help us see how the DRI behaves when produced with hydrogen.

The Hamburg plant will have an annual production capacity of 100 000 tons, with nearly pure hydrogen as the reducing gas.

Technical Challenges of the Hydrogen DRI/Steel Project

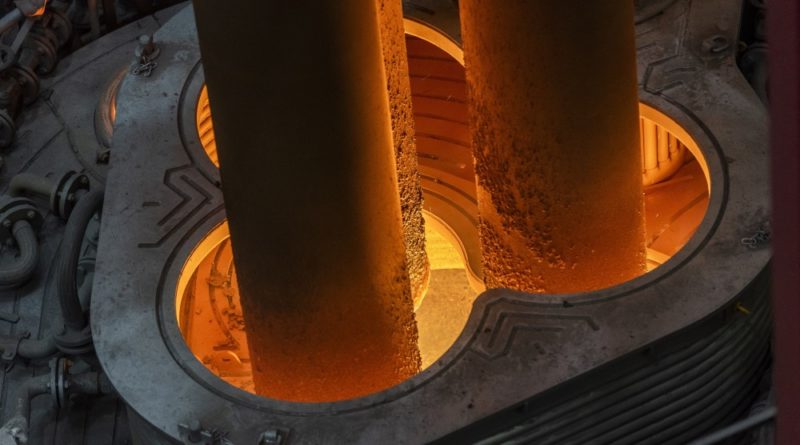

This will be the first DRI plant to utilize only hydrogen for reduction, so it’s understood that the thermal balance of the furnace will be slightly different. The plant design will draw on Midrex’s deep understanding of the thermodynamics of direct reduction derived from 50 years of supplying Midrex plants around the world, some utilizing more than 80% hydrogen.

ArcelorMittal has combined extensive practical know-how in the operation of direct reduction furnaces using various reducing gas sources, and their expertise in plant operation will be very valuable in effectively demonstrating direct reduction with hydrogen.

Perhaps of most interest to the project team will be how the DRI performs in the EAF. This will be an important milestone for carbon-neutral steelmaking. The ArcelorMittal Hamburg team has years of experience in EAF operations, which will be very beneficial during these trials.

ArcelorMittal has more DRI-EAF experience than any other steel company in the world. Their Hamburg plant is the only direct reduction plant in Western Europe and already has one of the lowest CO2 emissions of any industrial facility in the European Union (EU).