Jubilee Metals targets 450 tonnes per month of cobalt hydroxide

Jubilee Metals Zambian operations faced severe power and water interruptions over the period, which extended into January 2023, and impacted its ability to operate as intended and effectively.

During the period the Sable Refinery continued to expand its operational capability through the addition of the copper sulphide refining circuit and the successful completion of the operational trial to produce cobalt hydroxide saleable product.

The water infrastructure was successfully upgraded during December 2022, with the implementation of new private infrastructure under licence from the Zambian authorities. A further concerted joint effort between the Jubilee teams and the Zambian authorities to alleviate the reduced power availability, has resulted in an action plan that addresses not only the immediate operational challenges, but also offers an incentive to accelerate the roll-out of Jubilee’s copper and cobalt expansion strategy in Zambia.

The jointly agreed and implemented new power management plan better synchronises operational planned maintenance with scheduled power outages to ensure more consistent and stable operations for a prolonged period.

Simultaneously power and water infrastructure has been upgraded to offer operations, such as Roan, the opportunity to expand its operational footprint. The benefits of the new joint power management plan are clearly visible in the improved stability of power and operations and the impact on operations will be better reflected during the second half of FY2023.

During the period under review, and to mitigate the risk of equipment damage and loss of product quality caused by outages, management has taken the decision to curtail copper production at Sable and instead increase stockholding of partially processed material at its Roan concentrator, which is targeted to be refined at Sable following the implementation of the new power management plan.

Through the success of this intervention, Jubilee has updated its copper and cobalt expansion strategy to focus on maximizing its operational footprint through the expansion of existing operations to fully utilise the expanded available infrastructure.

This offers the opportunity to not only accelerate the implementation of the expansion strategy but also to reduce the early capital requirement through Brownfields expansion of existing operations. The expansive surface area supported by upgraded infrastructure at Roan, offers the potential to more than double the existing 780 000 tonne per annum

operational capacity at a significantly lower capital outlay than building a new Greenfields concentrator facility, and without the uncertainty of available infrastructure.

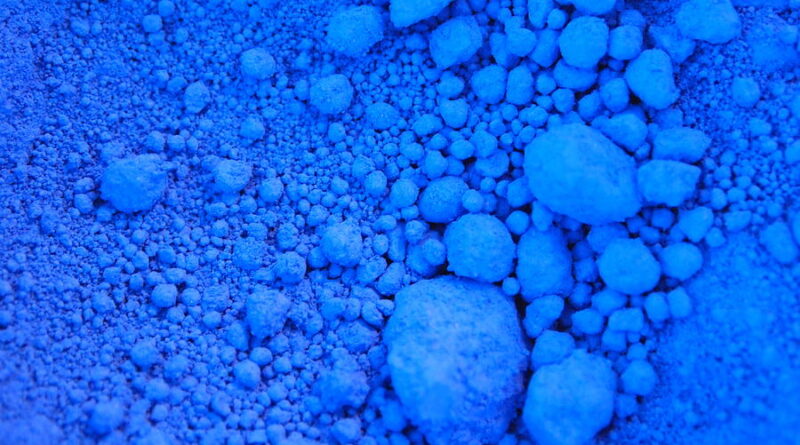

As a result of the successful cobalt production trials, the decision was taken by the Company to debottleneck and expand the cobalt refining capacity to increase Sable’s capability to produce saleable cobalt hydroxide concentrate from recycled waste materials in Zambia.

The debottlenecking of the circuit will be completed during February 2023 which, targets to increase the processing capacity of waste materials to an equivalent production rate of some 270 tonnes per month of cobalt hydroxide (75 tonnes of contained cobalt) from recycled waste alone.

A further expansion is currently under review to target some 450 tonnes per month of cobalt hydroxide (125 tonnes of contained cobalt) from recycled waste alone. The capacity is feed grade dependent and can be increased by further preconcentration of the secured feed supply. Sable’s ability to now pivot between metals offers the opportunity to offset a short-term reduction in revenues from copper production due to the expansion of Roan, with an increased higher margin cobalt output. This is of noteworthy value during a time when responsibly soured cobalt from recycled material has seen a significant increase in demand.